Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Belgrade Avoids Arsenic with New Wells and Treatment Plant

From the Fall 2013 Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

|

The central Minnesota city of Belgrade has been supplying water to its residents for nearly 70 years. Its first plant was built in 1945, and in 1961 the city added gravity filters to remove iron and manganese. A 28,000-gallon tank for backwash was built in 1995.

As Belgrade grew to more than 700 people at the turn of the century, the city also faced the news that the federal standard for arsenic would be lowered soon. In 2006, the maximum contaminant level (MCL) went down from 50 parts per billion (ppb) to 10 ppb.

At the time, Belgrade was using two wells adjacent to the treatment plant. One was low in arsenic, but the other had levels around 40 ppb. By blending the wells, the city was able to comply with the stricter MCL - barely. The “barely” was added by public works superintendent Tony Olson, who also said that the low-arsenic well was “slowing down,” leading to fears that it would not be able to continue to produce enough water needed for the blending.

The treatment facility was also showing its age, and it was apparent action was needed for the city to continue to meet its average daily demand of 90,000 gallons and peak demand of 240,000 gallons.

A pilot study, conducted with SEH, Inc,. in the winter of 2009-2010, showed that new wells and a new backwash tank were needed and that a new plant would have to be built or the existing one rehabilitated.

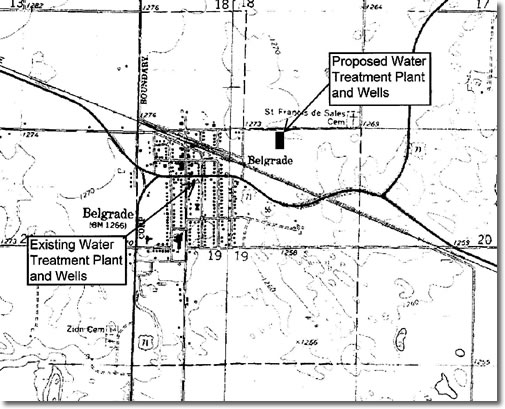

A test well located in an industrial-park area in the northeast section of Belgrade indicated a water source with no arsenic but with higher levels of iron and manganese. The city drilled two new wells, ranging in depth from 187 to 189 feet, in this area.

“They were lucky enough to find these wells that don’t have arsenic,” said Jeff Ledin, a member of the SEH design team, along with Chad Katzenberger and John Thom. “Iron’s great. We can treat that all day long. Arsenic - we have to work at that.”

As part of the pilot study, the design team, public-works officials, and city council members toured nearby plants in Richmond, Clara City, and Kensington. In addition to the treatment processes in those plants, the group paid attention to the building and facilities design. “We learned to separate the office and controls,” said Olson. “It’s not as noisy.”

At the conclusion of the study, the city opted for a new treatment plant adjacent to the wells in the industrial park with a backwash tank outside the plant. A new plant eliminated the need for a line from the previous site to the new wells, and the 30,000-gallon backwash tank reclaims about 80 percent of the water.

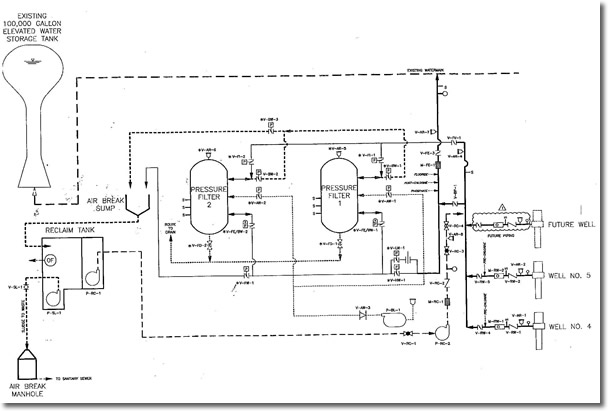

The new treatment plant has two pressure filters, each with 12 inches of anthracite on top of 18 inches of silica sand. Darren Braegelman, who operates the plant, said chlorine and fluoride, along with a polyphosphate for corrosion control, is added to the water after it passes through the filters. Single-stage pumping from the wells gets the water to residents.

|

| The new Belgrade water treatment plant is in an industrial park in the city's northeast corner and has two pressure filters. |

|

The new plant went on line March 17, 2011. Its masonry exterior fits with the surroundings of the industrial park. The old plant was demolished and the wells sealed although the 100,000-gallon tower on the previous site remains.

The final cost of the project was $1,687,000 and financed with a slight increase in water rates as well as through a combined loan and grant package from the Minnesota Department of Health Drinking Water Revolving Fund and Public Facilities Authority in addition to a small city’s grant from the Minnesota Department of Employment and Economic Development.

|

| A schematic drawing of the treatment process in Belgrade. |