Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Bemidji Builds Treatment Plant to Remove PFAS

From the Summer 2022 Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

With more than 15,000 residents, Bemidji is the largest commercial center between Duluth and Grand Forks. While Lake Bemidji is the northernmost lake feeding the Mississippi River, Bemidji can boast of being “The First City on the Mississippi.”

Bemidji is known for the large and mythical, most notably with a statue of Paul Bunyan, but it has its share of real (albeit smaller) personalities. Born in Bemidji, Jane Russell moved to California and ended up with a star on the Hollywood Walk of Fame. Charles Scrutchin was a pioneering African American lawyer who came to Minnesota in 1898 and began practicing law in Bemidji. And the body of Lobo, a wolf who killed more than 100 deer a year before being captured, is stuffed and on display at Morrell’s Chippewa Trading Post in Bemidji.

A popular destination, Bemidji is accessible by highways, and it is also a regional hub for air travel. Its airport, in the northwest corner of the city, has been used as a training area for firefighters. As was the case at many sites around Minnesota, the airport executed required firefighting training using Class B firefighting foams, which are used for flammable liquid fires. Class B foams—also known as aqueous film-forming foam (AFFF)—contain per- and polyfluoroalkyl substances (PFAS), which for years were used in the manufacturing of a number of products, including nonstick cookware coatings and carpet and textile finishes.

In the early 2000s, PFAS began to be detected in soil and groundwater at sites that used AFFF for firefighting training. Concerns about impacts on drinking water became acute at training sites that were near wells. Along with the Minnesota Pollution Control Agency, the Minnesota Department of Health (MDH) began sampling water supply systems around the state at locations where AFFF was used for training.

The old and new water treatment facilities in Bemidji. The one in the foreground will be demolished in the next phase of construction.

The Bemidji water treatment facility is located on the edge of the airport property, and Bemidji’s five wells—ranging in depth from 150 to 180 feet—are on airport property. The city’s water treatment entailed sequestering iron and manganese at each well using polyphosphate and adding fluoride and chorine at the facility.

Backwashing at the Bemidji facility.

MDH district engineer Todd Johnson said they found no traces of PFAS in Bemidji’s water during sampling in 2009. However, low levels were detected in 2015 with sampling performed for the U. S. Environmental Protection Agency’s (EPA) third Unregulated Contaminant Monitoring Rule. The monitoring results were higher than most sites tested across the state, so MDH continued sampling on a quarterly basis. In 2017, MDH lowered its health-based guidance values (HBVs) for PFAS. “That’s when things started to pinch the cities,” said Johnson.

When the guidance values were updated in 2017, the PFAS levels in two of the wells exceeded them; MDH issued a health advisory for those wells and eventually for all of the wells. Bemidji responded by hiring Barr Engineering Company of Minneapolis to identify immediate and long-term actions to maintain compliance and provide safe drinking water.

Taking Action

Two of Bemidji’s wells had higher levels of PFAS than the others. The city was able to supply water below the MDH guidance levels by primarily using the wells with the lowest PFAS concentrations. Groundwater modeling was performed to predict how quickly the water quality would change with the modified pumping schedule.

Barr and the city also explored three sites for a new wellfield, locations that would be close to the existing facility but far enough away to be out of the PFAS contamination plume. MDH engineer Eric Weller said a test well at the north end of the airport, upgradient of the plume, had issues with heavy metals. “The new well would have drawn in undesirables,” said Todd Anderson, the water plant superintendent.

Although it came up short on finding a suitable alternate water supply, the city wasn’t fazed. Concurrent with looking at a new wellfield, Bemidji pilot tested treatment technologies to remove PFAS from its existing wells.

Treatment Options

Barr and the city studied granular activated carbon (GAC) and two different single-pass ion exchange resins. Barr facilitated a GAC accelerated column test, a common method for assessing breakthrough curves and identifying which PFAS compounds would show up in the effluent first as the carbon was exhausted. In addition, an on-site pilot test for ion exchange treatment was operated by city staff.

Based on results and costs of the different treatment technologies, Bemidji selected GAC as the long-term option. The versatility of GAC in dealing with PFAS and other contaminants of emerging concern, ones that may require treatment in the future, was one of the factors in the decision.

During the accelerated column and pilot testing, Johnson noted that iron and manganese fouled the treatment media. Pretreatment was needed, and, as a result, iron and manganese treatment (five vessels filled with anthracite and greensand) was added to the final design. “It killed two birds with one stone,” said Johnson, as the pretreatment has improved the overall aesthetic quality of the water while keeping iron and manganese from fouling the GAC media. The GAC vessels consist of three lead/lag treatment trains for a total of six filters.

Because iron and manganese are removed at the plant, polyphosphate is no longer needed at the wells; however, because of additional pressure created by the new treatment systems, the city has upgraded the pumps at two wells with plans to upgrade the other three in a future phase.

The greensand filters for iron and manganese treatment are on the left, the granular activated carbon filters for removal of PFAS on the right.

Plant Options

Because of the need to implement treatment as soon as possible, the city considered having temporary treatment for PFAS removal before constructing a full-scale plant. “First we looked at a tent and then a shed as a way to temporarily house the treatment equipment,” said Anderson. However, Barr found that a permanent plant, constructed with pre-cast concrete panels, could be built while still meeting the city’s timeline.

Craig Gray, Bemidji’s public works director and city engineer, said, “By the time we ran all the numbers, we decided we would have wasted money,” referring to using a temporary plant. By building a permanent plant, “None of this will be wasted money.”

Because of the time crunch for getting moving, Bemidji issued four separate bid packages. The first three were for the procurement of concrete panels and the treatment equipment systems. The fourth was for the general contractor, Rice Lake Construction of Deerwood, Minnesota, which then incorporated the first three bid packages into their scope. Normally bid as one package, the construction was accelerated with this method, and the (Phase I) plant began continuous operations in March 2021, only 14 months after the start of design.

“It went really well,” Johnson said. “There were no coordination issues.”

The city covered the $7.5 million cost for design and construction through the sale of utility bonds and a rate increase of seven percent.

What’s Next?

Bemidji isn’t done. The city knew that the new Phase I plant was only the first of multiple phases. The plant was designed with knockout panels at the east end that could be removed for future expansion.

The Phase I plant capacity is 1,500 to 1,800 gallons per minute (gpm). Gray said their summer peak is 2,100 gallons per minute, which they can meet with the 1.75 million gallons of storage in three towers. Phase II will add four greensand filters and two trains of GAC vessels, bringing the capacity to 2,500 gpm.

Construction for the expansion will begin in the summer of 2022 and includes a new structure for chemicals, offices, and a garage. When this work is completed, the existing plant, which now has the chemical feed equipment, will be demolished.

Phase II is being covered with $10.2 million the city is receiving from a state bonding bill passed in 2020. Bemidji has a two-year construction time frame, from June 2022 to June 2024, to account for potential supply issues with concrete panels and treatment equipment.

In addition to the bonding bill, the city received $12 million from a settlement with the 3M Corporation, which manufactured the PFAS contaminants. This money will be used for maintenance and operation for the next 50 years. Gray anticipates replacing the GAC every two to three years, a tab that, with disposal of the used carbon, will cost about $200,000 each time.

The new plant is removing PFAS from the water supply as well as keeping the plume from migrating to private wells to the east. In addition to the MDH guidance values that have been established and revised, the EPA is expected to set maximum contaminant levels for perfluorooctane sulfonic acid (PFOS) and perfluorooctanoic acid (PFOA), two specific PFAS substances.

“As we got going,” said Anderson, “we didn’t know if we were looking at a five-year, 50-year, or 400-year problem.” With its new plant, Anderson and the others are confident that the city will be able to successfully navigate future treatment needs.

“This will take care of us for a long time,” said Gray, who also credited Weller and Johnson, the MDH engineers in Bemidji, for their contributions. “The local MDH office helped us big time.”

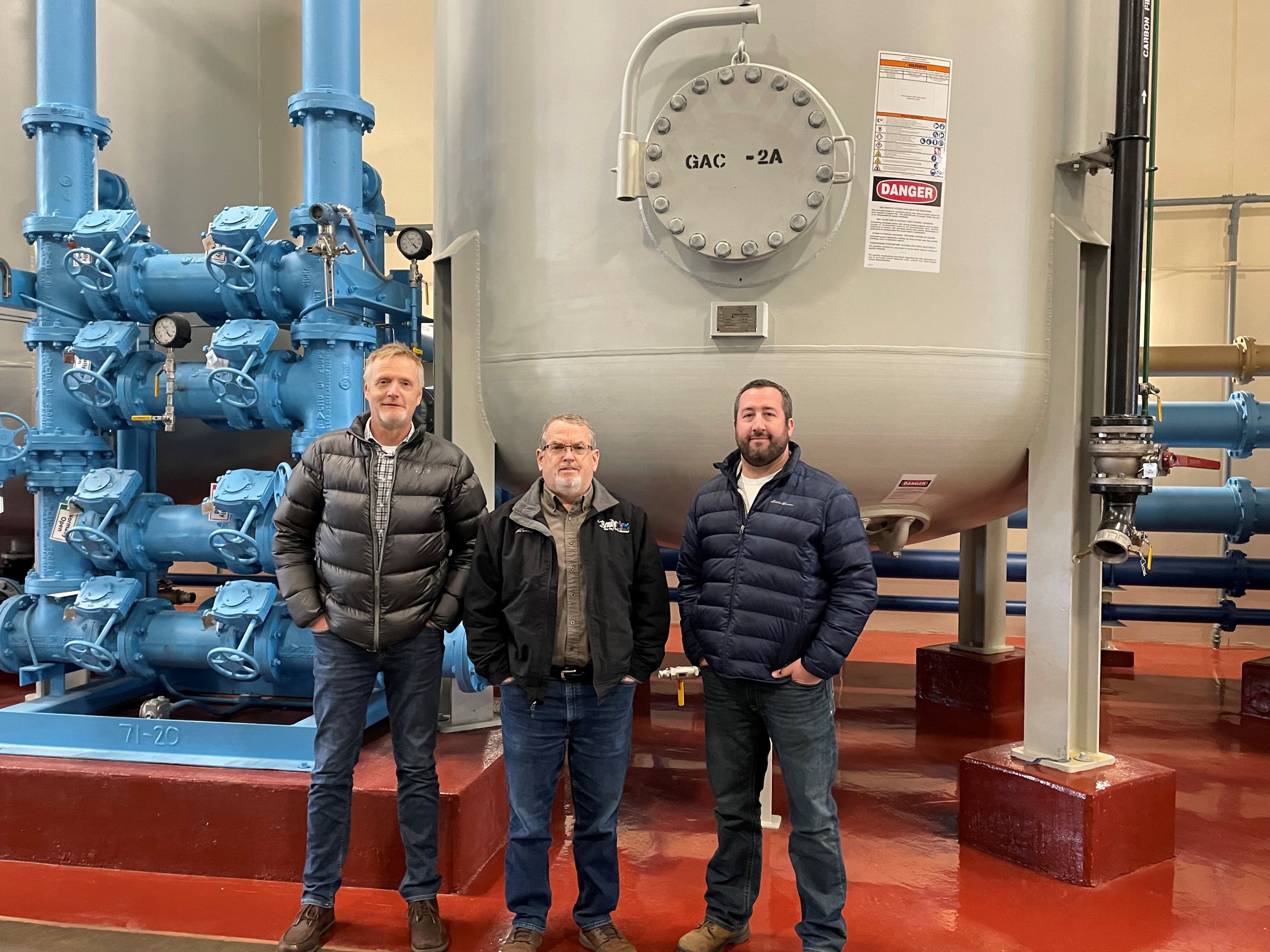

Todd Johnson, Craig Gray, and Eric Weller in front of one of the GAC filters.

Go to > top.