Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Water Supply Around the World

From the Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

- Barrow, Alaska

- Death Valley, California

- New York City

- International Falls, Minnesota

- Reykjavík, Iceland

- Dry Tortugas, Florida

Real northern exposure

From the Winter 1993-94 Waterline

Minnesota water operators face challenges brought on by the state’s grueling winters. But consider the obstacles to be encountered as one gets farther north—specifically, to Barrow, Alaska, 330 miles above the Arctic Circle. Despite the rigors of the harsh climate, Barrow maintains a potable water supply for its 3,500 year-round residents.

Barrow gets its supply from a freshwater reservoir, less than a half-mile inland from the Arctic Ocean. This was originally part of a larger salt-water lagoon that was separated into three bodies of water with the construction of earthfill dams.

The process to convert the upper reservoir into a freshwater source began the first winter after the dam creating it was built. With the ice formed to its maximum thickness, more than half of the entire fresh water volume of the reservoir was contained in the ice; the water remaining below the ice contained most of the salinity. A few million gallons of water was then pumped out from beneath the ice, removing concentrated salt brine, and discharged into the ocean. The melting of the ice in the spring diluted the reservoir. Repeating this procedure for several years finally reduced the salt content of the reservoir to acceptable drinking water levels.

In the meantime, reverse-osmosis (R-O) was used to help desalinate the water. Although it is no longer needed for that purpose, reverse-osmosis is still used to remove organic precursors for trihalomethanes. Conventional treatment—aluminum sulfate for coagulation, flocculation, sedimentation, and filtration with mixed media sand filters—is performed prior to the R-O.

The reservoir is 40 feet deep with the intake structure extending out a 20-foot trench at a depth of 35 feet. The ice in the winter averages 7-to-8 feet so there is no worry about a lack of open water.

The delivery system for the water is also distinctive. Polyethylene pipes carrying the water, along with conduits for other utility services, snake through the Barrow Utilidor System, an insulated wooden tunnel built in the permafrost six feet below the streets.

A recirculation system keeps the water moving at all times to prevent freezing in the pipes—not so much within the utilidor but inside customers’ homes, which have both supply and return lines to maintain circulation. In Barrow homes and businesses, flow does not stop when a faucet is turned off; rather, the water passes through a loop and returns to the pipe in the utilidor to keep it circulating through the system.

As is the case with almost anything else, Barrow residents pay more for their water than do people in the Lower 48 or even in other parts of Alaska. A major reason for the higher prices is freight costs. All goods must be brought in by air or by barge. And since the Arctic Ocean around Barrow is ice-locked for all but two months of the year, purchases must be planned carefully for the entire year. “The freight on the chemicals we use in treatment costs as much as the chemicals themselves,” says Tim Wolfe, the Utility Plant Superintendent for Barrow Utilities and Electrical Cooperative, “and that’s when we bring them in by barge. I don’t even want to think about how much they would be if we had to have them flown in.”

So cheer up, Minnesota. It could be worse.

Go to > top.

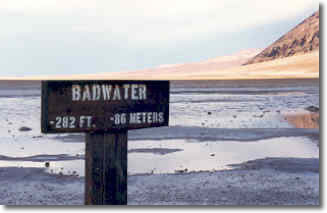

Badwater (But at least the food’s good)

From the Spring 1995 Waterline

Badwater is actually just the name of the portion of Death Valley in California that drops to 282 feet below sea level, the lowest point in the United States. Although the water here is too high in salt content to be potable, springs in Death Valley National Monument provide an adequate drinking water supply for the resorts and campsites that serve the many tourists who visit each year. In the past, these springs were the water source for the miners and 20-mule team trains that mined borax from the region.

Badwater is actually just the name of the portion of Death Valley in California that drops to 282 feet below sea level, the lowest point in the United States. Although the water here is too high in salt content to be potable, springs in Death Valley National Monument provide an adequate drinking water supply for the resorts and campsites that serve the many tourists who visit each year. In the past, these springs were the water source for the miners and 20-mule team trains that mined borax from the region.

All aspects of water supply—collection, treatment, and distribution—are performed by the U. S. National Park Service. The 88-degree water is collected from the Texas Spring Tunnel and underground infiltration galleries at two different locations. The total daily collection capacity is two million gallons per day.

The only normal treatment of the water is disinfection by addition of chlorine to maintain a free chlorine residual. Water samples are analyzed twice a month for possible bacterial contamination by the Inyo County Health Department. Salt at approximately 150 milligrams per liter is considered to be at a low level.

Fluoride is the only element of the Death Valley water supply that is above the California Health Department limit. The National Park Service issues advisories to tourists that the fluoride levels will not cause health problems but could cause dental enamel discoloration if consumed over an extended period of time.

Go to > top.

New York City

From the Summer 1998 Waterline

This year (1998) marks the 100th anniversary of New York City as we now know it. In 1898, New York (already the largest city in the nation even though it consisted of barely more than the island of Manhattan) was consolidated with Brooklyn (then the nation’s third largest city) and nearly 40 other townships and communities to form a new city, divided into five boroughs, that brought an increased demand for a variety of services, none more important than an adequate supply of potable water. New York continues as America's largest city and, as such, has the nation’s largest drinking water system.

But while New Yorkers fret about bridges and subways and other worries dealing with an aging and crumbling infrastructure, they continue to draw water from taps with little thought of where it comes from. “Although the city’s water supply is one of its major wonders, probably it is among all of them the least remarked, partly because it is largely hidden from view and even more on account of its trifling cost,” wrote Arthur Warner in a 1932 feature in the New York Times Magazine. “With the natural metropolitan tendency to respect only that which is expensive, the average citizen does not pause to consider a product which costs him three-fourths of a cent a day.”

Such complacency is not unique to New York. But the sheer magnitude of this city’s drinking water supply, treatment, and distribution process merits a closer look.

During the 1600s, when most of the city’s population lived in lower Manhattan, residents drew their water from local wells, streams, and ponds, including a 48-acre, spring-fed pond known as the Collect. By the 1780s, though, the quality of the Collect had declined because of dumping of garbage, slop buckets, and even dead animals. In 1803, the city began filling the Collect and placing greater reliance on underground sources and pump-operated public wells. The quality of the well water varied greatly, and there were outbreaks of typhoid fever, yellow fever, and other diseases, capped by a cholera epidemic that killed 3,513 New Yorkers in 1832. The need for a dependable source of water was becoming more apparent, and three years later New York voters approved the damming of the  Croton River in Westchester County to the north and funneling the collected water into the city.

Croton River in Westchester County to the north and funneling the collected water into the city.

The 1842 opening of the Croton Aqueduct—a 41-mile canal covered with stone and brick—set off a great water celebration with parades, fireworks, and fountains shooting plumes of water 50 feet into the air. Having a dependable supply of safe drinking water allowed the population of New York to grow, eventually to the point that the Croton system was unable to keep up with the city's needs (even though it had been enlarged with a new dam and aqueduct, and a larger watershed).

Early in the 20th century, the state authorized New York City to purchase watershed land in the Catskill Mountains (approximately 100 miles to the northwest) and to create new reservoirs by damming streams and rivers. Residents of several villages were forced to move as the towns were flooded to create the reservoirs. The entire New York City water supply system now encompasses three watersheds with a total area of 1,969 square miles; it has a combined storage capacity of 550 billion gallons provided by 19 reservoirs and three controlled lakes and delivers, on average, 1.34 billion gallons a day to the eight-million residents of New York City in addition to another one-million people in adjoining counties.

The Croton watershed, which supplied the original solution to New York’s water problems, now accounts for only ten percent of the water supplied to the city. However, there are still reminders of its legacy, none more prominent than the High Bridge over the Harlem River, connecting Manhattan and the Bronx, a portion of the original aqueduct which is now a historic national landmark and a continuing symbol of the significance of water.

Go to > top.

In the Northlands

From the Summer 1999 Waterline

Northern climates can pose challenges to all sorts of different situations, including the production and delivery of a potable supply of water. This issue of the Waterline profiles the water systems of International Falls, Minnesota, and Reykjavík, Iceland.

Taking control of its water destiny

In many ways, the city of International Falls, Minnesota, is dominated by the paper-processing firm of Boise Cascade. The bridge across the Rainy River, which connects the city with Fort Frances, Ontario, is owned and operated by Boise Cascade. The public is allowed to drive across the bridge—for a fee.

But while international access in the area may be under the control of a conglomerate, no longer is that the case with International Falls’s most precious resource—its supply of drinking water. Until 1991, the city had purchased its water from the Boise Cascade Corporation. Boise Cascade used 20 million gallons a day in processing paper products and sold approximately 1.2 million gallons a day to the city of International Falls for its water supply. The treatment performed on the water was alum flocculation plus the addition of fluoride and chlorine.

In the mid-1980s, the city began exploring options to construct its own water treatment plant. Boise Cascade encouraged International Falls in these efforts and even arranged for an exchange of land to provide the city with a site along the Rainy River for the facility.

Having to treat all its water to potable standards, even though only a small percentage of it would be used for drinking purposes, was hardly efficient for Boise Cascade; in the late 1980s, the mill embarked on a major expansion that would increase its use of processed water by a third, which would have made it even less feasible to treat the entire supply. Other issues were the mill's desire to use coagulants that weren't allowed for drinking water as well as a concern about the ability to meet tougher drinking water standards.

Fortunately for all concerned, in 1991 a water treatment plant went on-line in International Falls. (Boise Cascade continued to produce its own process water and began purchasing potable water from the city.) For the treatment plant, water is taken from the Rainy River at a depth of 26 feet with the intake extending more than 1,200 feet from the United States shore—within 30 feet of the Canadian border. Larry Cole, the Minnesota Department of Health (MDH) district engineer for the area, says water in the Rainy River comes off the exposed bedrock of the Canadian Shield. “There’s nothing to erode into it,” says Cole, adding that the river’s pristine qualities aren’t necessarily good in terms of treatment. “It makes for the most difficult water to treat: soft and low in turbidity—and cold besides.”

Fighting Turbidity with Turbidity

The lack of turbidity in the raw water has been a major operational challenge since the plant opened, according to Tom Sakry, the treatment plant superintendent. It hampers the effectiveness of the flocculation stage, making it difficult to bring together colloidal particles—including viruses, protozoa, and bacteria—so they can be precipitated out.

The plant initially used alum as a coagulant but had to add soda ash to the head of the plant to make the alum function. “We had to produce the mini-floc recirculating back to the head of the plant in order to form a nucleus for our floc to form on,” Sakry explains. One-and-a-half years ago, the plant switched from alum to Nalco Ultrion 8155 and a non-ionic polymer with a higher molecular weight than alum. It enhanced the overall formation of the floc, resulting in improved sedimentation that has lowered the finished-water turbidity.

Although it may seem paradoxical, it is necessary to increase raw-water turbidity to decrease finished-water turbidity. “You have to dirty it up to clean it up,” says Cindy Cook of MDH.

Sakry says the Ultrion 8155 is “a bit more expensive but worth it.” In addition to the Ultrion reacting more quickly than alum in the water—particularly when the water is cold—it has helped in optimizing the system by eliminating a great deal of sludge and requiring less water for backwashes.

Filter Stages

The flocculation occurs in the first stage of the filters. The water then flows down through a bed of granular media (anthracite and sand), trapping the particles that are larger than the filter pores. Particles smaller than the pores become attached to the granular media of the filter by adsorption. Following filtration, the water is then disinfected with chlorine and chloramines; the treatment process is concluded with the addition of fluoride before the water enters the distribution system. The treatment plant serves the residents of International Falls as well as the nearby city of Ranier. “The plant is making good quality water,” Sakry says. “That I’m very proud of.”

Go to > top.

Thetta Kemur Allt Med Kalda Vatninu

Water in Iceland as Pure as It Comes

From the Summer 1999 Waterline

To visitors, Iceland is known for its hot springs and the therapeutic qualities they are said to bring. To residents, the island's primary therapeutic qualities are not from the geo-thermal springs but rather from cold water, among the purest in the world.

To visitors, Iceland is known for its hot springs and the therapeutic qualities they are said to bring. To residents, the island's primary therapeutic qualities are not from the geo-thermal springs but rather from cold water, among the purest in the world.

Water supplied to Reykjavík, the country's capital and largest city, is pumped untreated to homes from holes ranging from 10 to 80 meters below the surface to underground wells and springs, which are well protected from atmospheric or surface soil pollution. Because of Iceland’s isolation and sparse population, air pollution is not a problem compared to other industrial nations. As a result, the conditions are favorable to the production of potable water.

From the beginning, Iceland’s existence has depended on water; the island’s first settlers relied on access to potable water when choosing their settlement. It wasn't until early in the 20th century, however, work began on a water works company for the city of Reykjavík.

On June 16, 1909, water started to run through a pipeline that extended from the Elliða-rivers to Reykjavík, a process that began Reykjavík Water Works. Later in the year, the pipeline was continued to Gvendarbrunnar, a spot in Heiðmörk, a national park east of Reykjavík where the primary sources of water—wells, springs, and reservoirs—are located.

The completion of the water system brought about a sharp rise in consumption among Reykjavík residents, as they went from an average of 18 liters person per day to more than 200 liters. In the ensuing years, as the population of the city grew, with it came an increased demand for water, reaching a maximum level in 1986 when Reykjavík Water Works produced 30 million tons of water and requiring a wider and more complex distribution network.

Although the population of Reykjavík continued to rise, the amount of water distributed has been steadily declining since 1986, thanks to a series of conservation measures taken by the Reykjavík Water Works, including the use of computerized listening devices, which have enabled engineers on the ground to locate leaks in the underground pipelines.

In addition to employing the latest technologies in detecting leaks, conservation measures involve the constant renewal and repairs of old pipelines through trenchless digging, a more thorough monitoring of the distribution system, and a campaign to educate consumers on economical use of water. In the last ten years, despite a considerable increase in the city’s population, Reykjavík Water Works has reduced the amount of water pumped by one-third.

In 1994, water works companies in Iceland were classified by law as food production companies, bringing about strict regulations that specified food safety measures and health care issues. The following year Reykjavík Water Works decided to adopt and tailor a quality control system to its processing needs, according to the criteria of ISO 9000 standards. In addition to having its water tested and analyzed on a regular basis by the Reykjavík Health Authority, the water works company has an internal quality control system that fulfills the requirements for a food production company and aims to be one of the first water companies in the world with a certified quality system, a designation that will be important for the country’s exporters when trading in foreign markets.

“In the near future,” says Guðmundur Þóroddsson, the managing director of Reykjavík Water Works, “food production companies will probably be demanding certified quality water.”

The total number of customers supplied by Reykjavík Water Works is approximately 134,000; this number includes the nearby communities of Kópavogur, Seltjarnarnes, and Mosfellsbær, which purchase water from the company but have their own distribution system.

“Thetta kemur allt med kalda vatninu.”

Translated literally, this means “It’ll be all right when the cold water comes.” This phrase was first used when Reykjavík Water Works was in the planning stages more than 90 years ago.

It is still used today as a phrase meaning, “In the end, everything will be all right.”

Notes on Icelandic Water:

Icelandic legend claims that the spring water blessed by Guðmundur Arason—an 11th-century bishop—was not only exceptionally healthy, it contained supernatural characteristics that allowed it, among other things, to extinguish fires faster than other water. A more recent legend attesting to the quality of the water involves a New York laboratory that was unable to detect any impurities in samples of water from Iceland. Unconvinced that any water could be this pure, the laboratory technicians were convinced their analytical equipment was not operating properly but had no more success in finding malfunctions in their equipment than they had in finding impurities in the water. As for hot water, the landscape surrounding Reykjavík is dotted with geo-thermal water storage tanks, including a set that surround a popular restaurant known as The Pearl. Geo-thermal water has a distinct smell since it contains a small quantity of dissolved hydrogen sulfide. Water is free of bacteria, and the calcium content is low, making it good for washing. For showers, the water temperature is adjusted not through the addition of cold water but by directly regulating the temperature of the hot water being delivered.

Dry Tortugas live up to name

Final Islands in the Florida Keys Bereft of Fresh Water

From the Spring 2005 Waterline

At the end of the Florida Keys—approximately 70 miles to the west of Key West, the terminus of U. S. Hwy. 1—is a cluster of small islands known as the Dry Tortugas. Discovered by Ponce de Leon in 1513, they were first named Las Tortugas due to the abundance of sea turtles. The word “Dry” was soon added to mariners’ charts to warn of the lack of fresh water.

At the end of the Florida Keys—approximately 70 miles to the west of Key West, the terminus of U. S. Hwy. 1—is a cluster of small islands known as the Dry Tortugas. Discovered by Ponce de Leon in 1513, they were first named Las Tortugas due to the abundance of sea turtles. The word “Dry” was soon added to mariners’ charts to warn of the lack of fresh water.

The Tortugas were fortified in the mid-1800s with the construction of Fort Jefferson, which also became a military prison for captured deserters as well as four men convicted of complicity in the assassination of Abraham Lincoln. The prisoners included Samuel Mudd, the doctor who treated John Wilkes Booth, Lincoln’s assassin.

For water supply in the fort, engineers devised a system to collect rain water and pass it through sand filters on its way to the more than 100 cisterns in the fort. The cisterns had a capacity of 1.5 million gallons. As the fort foundations settled, however, sea water leaked in, making the water undrinkable. With over 1,200 people here during some of the Civil War years, the Army secured two steam condensers capable of distilling 7,000 gallons per day from sea water—if fuel arrived from the mainland.

Today, visitors to the Tortugas must bring their own water. As for waste, the key has some recycling toilets that use no water or chemicals. The waste is composted in equipment below the outhouse building. However, when the ferry from Key West is docked at the Tortugas, from approximately 11 a.m. to 2:30 p.m. each day, people use the facilities on the ferry. The toilets on the Tortugas are used only by campers, National Park staff, and those arriving by plane outside of the hours that the ferry is docked.

|

| Fort Jefferson, which occupies 11 of the 16 acres of the key it is on, is surrounded by a moat. The island has no fresh water. |

Go to > top.