Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Schell’s Starts with the Water

From the Summer 2013 Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

|

| Opened in 1994, the New Ulm water treatment plant serves more than 13,000 residents and provides water to Schell’s Brewery, which performs additional treatment to make Schell’s Beer. |

“The first thing you start out talking about is water quality,” says Jace Marti. “It’s the main ingredient in beer.”

Marti is a brewmaster at Schell’s Brewery in New Ulm, Minnesota, and a sixth-generation descendent of August Schell, who co-founded the brewery in 1860. A native of Durbach, Germany, Schell came to the United States in 1848 and found his way to New Ulm. Not finding any of the German beer he was fond of in the area, Schell started a brewery, using an artesian spring as a water source and the nearby Cottonwood River for transportation of the finished product.

At the time, most of the brewing was done in the winter, and the beer was kept in caves—staying cool with blocks of ice from the river—for aging and fermentation and to store the product for the peak summer months.

|

| Jace and Ted Marti in the old brewhouse, built in the 1880s. |

Schell’s survived the Dakota War in southern and western Minnesota in 1862 and expanded. The brewery and grounds now cover 40 acres with scenic gardens, a deer park (in addition to a year-round residency of peacocks) and a mansion, making it a popular tourist destination in the summer as well as the site of the annual Bockfest event in the winter.

Eventually the springs were replaced by wells. In 1995 Schell’s switched to water provided by the city, which opened its water treatment plant. City water comes from the quaternary buried artesian and undifferentiated cretaceous aquifers, tapped by 13 wells, ranging in depth from 62 to 247 feet.

Joel Johnson, the chief operator for the New Ulm utility, said they feed potassium permanganate and chlorine for manganese and iron removal and have five sand filters at the city's water treatment plant. New Ulm averages 2.5 million gallons per day (MGD) throughout the year with the production reaching about 3.5 MGD during the summer. Of that amount, Schell’s uses approximately 1.2 million gallons per month in brewing 130,000 barrels of beer a year.

Marti says the brewery is still getting water from the same aquifers as it had during the time it had its own wells. The groundwater, with its iron and hardness, is more suited to brewing English-style ales, Marti explained, adding that the New Ulm water profile is similar to England’s Burton upon Trent, a major brewing city.

The German lagers and Pilsners require softer water, and the brewery performs its own water treatment, which includes reverse-osmosis and an iron filter at the head of the brewing. The water treated at the municipal plant is then blended with more city water with the goal of reducing the hardness to 50 parts per million.

“There are certain elements [of the water] good for brewing and some that aren’t,” said Ted Marti, Jace’s dad and the company president. Ted attended Siebel’s Institute of Brewing in Chicago and has been a brewmaster since 1975. Jace went to school in Berlin and became a brewmaster in 2011. Besides Ted and Jace Marti, Schell’s has two other brewmasters, Jeremy Kral and Dave Berg, among its 57 full-time employees.

|

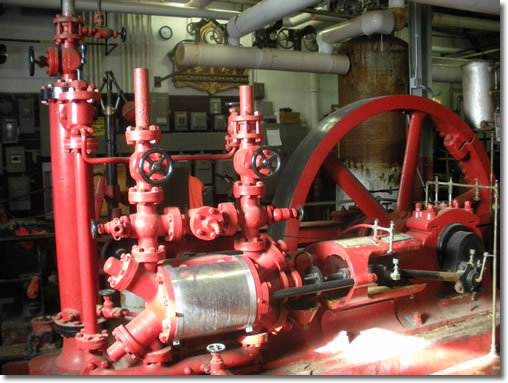

| Equipment from 1885 and current equipment (above), the reverse-osmosis unit, at Schell’s. |

|

In addition to eight year-round specialty brands and eight seasonal brands, Schell’s now brews Grain Belt Beer with three different labels. Grain Belt used to have a large brewery in northeast Minneapolis, but the facilities have been converted to a library and space for other uses. The Twin Cities also had Hamm’s and Schmidt breweries, but Jace Marti notes that consumer preferences have been changing with the craft-beer revolution.

Schell’s remains one of the few large breweries in the state, along with Cold Spring in central Minnesota. Summit Brewing in St. Paul has also risen in prominence.

From the micro-breweries to full-scale facilities for beer production, it all starts with the water.

|

| Peacocks are year-round residents on the grounds of Schell’s Brewery in New Ulm. |

|

| Vats in the brewing room are used to separate the grain from the liquid (left). Watermains from the 1800s, when a cistern was used for water storage, are still visible (right). |

Of Interest

Go to > top