Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Plate Settlers Clean Up Ortonville Water

From the Winter 2017-2018 Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

Separated from South Dakota by Big Stone Lake, Ortonville is a small and thriving community in western Minnesota. At the end of the last Ice Age, the lake was at the southernmost extent of Lake Agassiz, which reached all the way to what is now Winnipeg. Fed by the melting glaciers that carved Minnesota’s topography, Lake Agassiz drained into the great River Warren, the predecessor to the Minnesota River, which meanders from Big Stone Lake through southern Minnesota to its confluence with the Mississippi River at Fort Snelling in the Twin Cities. Though its history includes being part of the largest body of water in North America, Ortonville uses wells to supply its 1,900 residents as well as Big Stone City, South Dakota. Its history of water supply is diverse and includes a recent upgrade of its water treatment plant with plate settlers installed as an innovative and cost-effective solution to improving the quality of the water.

Stationed on Big Stone Lake in Ortonville, a 1933 building originally housed pumps to get water from a pair of wells to residents in higher parts of the city.

High levels of iron and manganese in the groundwater prompted the city to add filters and transform the facility into Ortonville’s first water treatment plant in the 1960s.

In 1997 Ortonville teamed with Big Stone City, across the lake in South Dakota, to open the Big Stone Area Treatment Plant, one that serves both cities. Two wells in sediment in the river plain pump water to the treatment plant, which is farther inland than the previous one and on a hill about 400 feet higher than the wells.

The new plant included a flocculation basin, unlike the direct filtration in the original plant, to allow detention time for contaminants, reducing the amount of iron and manganese that reaches the filters. The plan for the 1997 facility was to add lime softening, but the process was dropped because of the cost. The hardness of the water in the ground is approximately 1,100 parts per million (ppm) as calcium carbonate. Most residents of Ortonville have water softeners in their homes.

|

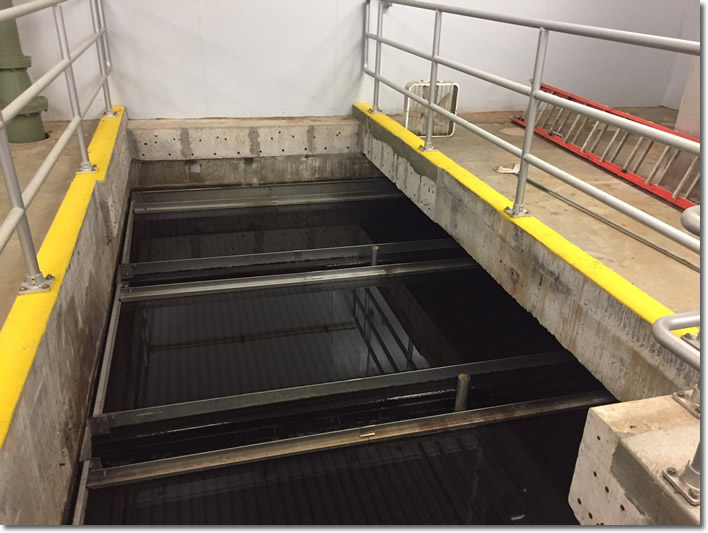

| Plate settlers (above) were added to the treatment process in Ortonville to reduce the load on the filters (below). |

|

The raw water also has 5 ppm of iron and .5 ppm of manganese, both high enough to cause noticeable aesthetic effects in the water. The new plant did its job in lowering the iron and manganese levels while producing about 1,000 gallons per minute. High service pumps delivered water across the state line to Big Stone City, which has a smaller population (about 450) but also provides water to an ethanol plant.

However, the filter runs at the plant were short, often only five hours. John Thom of SEH, Inc. of Vadnais Heights, Minnesota, says the raw water is high in organic matter, causing problems with the oxidation of the iron in pre-treatment. The result was short circuiting in the flocculator, resulting in too much load on the filters.

SEH, Inc. worked with Ortonville on a pilot study to explore remedies and chose plate settlers as the solution. The city considered but rejected the costly option of adding to the building. Instead, it moved a stairway, put in flocculation basins, and reused the old detention tanks as plate settlers.

|

| Above: the original plant, which was a booster station for wells by the lake when it opened in 1933. Below: the 1997 plant, which retained its original size despite the addition of plate settlers. The beams and plate settlers were hoisted to the roof and brought in through a second-story door. |

|

Plate settlers have long been used in wastewater treatment. Their more-recent use in water plants has been for backwash reclaim. “Here, they are used for the iron and manganese removal,” said Thom, who explained that incoming water is aerated and then has chlorine, permanganate, and a polymer added as it enters the flocculation basin. “Then it flows in under the plate settler, and the particles rise. The plates are slanted. Particles travel up in a straight line, settle to a plate, and fall back into the sludge collector. Clear water comes off the top.”

Rather than 4 to 5 ppm of iron reaching the filters, now only about .5 ppm gets there, a 90 percent reduction in filter loading. Manganese dropped from .5 ppm to .1 ppm because of the plate settlers. “Instead of short filter runs, they are now pushing 100 hours although they will backwash at least once a week,” said Thom. “Before, they couldn’t recycle the water. It was all going to ponds. Now only the sludge goes out.”

Recovering the backwash water will result in less water usage, enough that the savings in water will cover the project cost, approximately $750,000, in six or seven years. Said Thom, “We got a big impact with a small outlay of dollars.”

|

| Above: Ortonville’s two wells, near Big Stone Lake. Below: Ortonville operator Sam Berger with John Thom of SEH, Inc. |

|

Go to top