Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Red Wing Plants Serve Water across Varying Elevations

From the Fall 2008 Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

The city of Red Wing has served its growing population with water for more than 100 years. Through much of the 20th century, treatment consisted of chemical addition at booster stations scattered around the community. By the late 1990s, however, radionuclides in the groundwater forced the city to consider alternatives for more advanced treatment.

The city of Red Wing has served its growing population with water for more than 100 years. Through much of the 20th century, treatment consisted of chemical addition at booster stations scattered around the community. By the late 1990s, however, radionuclides in the groundwater forced the city to consider alternatives for more advanced treatment.

Approximately 50 miles from the Twin Cities, Red Wing occupies the bluffs overlooking the Mississippi River, its varying elevation providing challenges with water distribution.

In the past, the utility added fluoride, chlorine, and ammonia at each of its eight booster stations. The use of chloramines rather than free chlorine helped in maintaining a residual to distant points on the distribution system. Water from the five wells was also aerated before going to ground-storage tanks to deal with hydrogen sulfide as well as iron and manganese.

The issue of radionuclides then came up in the 1990s. Levels of radium 226 and radium 228 ranging from 3.1 to 5.7 picocuries per liter (pCi/L) with gross alpha emitters as high as 21.9 pCi/L—both in excess of the maximum contaminant levels of 5.4 pCi/L and 15.4 pCi/L, respectively—prompted Red Wing to consider treatment alternatives.

The city hired Bolton & Menk, Inc. to study the situation and make recommendations. Lime softening was considered but rejected because of the cost and staffing needs. In addition, the utility needed to develop new wells to replace some of the existing ones, which were as much as 100 years old.

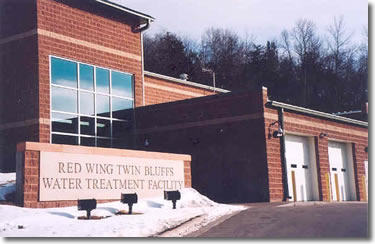

Red Wing decided instead to construct two new treatment plants to reduce the radionuclides as well as iron and manganese. One is the Twin Bluffs plant, on Pioneer Road to the southwest of downtown Red Wing, approximately 1,000 yards from Booster Station 7. The other is the Charlson Crest plant, off U. S. Hwy. 19 on the western edge of town to help serve the quickly growing Burnside area of Red Wing.

With the new plants came three new wells—one at the Twin Bluffs plant and two at the Charlson Crest plant—and the abandonment of three wells. The two remaining wells are by Booster Station 7. The wells are 630 to 655 feet deep, each producing 1,200 to 1,500 gallons per minute of water from the Mount Simon and Mount Simon-Fond Du Lac aquifers.

Corey Aadalen, a native of Red Wing, is the chief plant operator. He attended the water technologies program at Vermilion Community College in Ely, Minnesota, in the early 1980s and began working with the utility as an assistant water operator in 1984. Aadalen said the Twin Bluffs and Charlson Crest plants operate by the same process although they have different capacities: 5.7 million gallons per day (MGD) at Twin Bluffs and 4.3 MGD at Charlson Crest.

In the plants, aeration is performed. Small waterfalls provide a splashing action that increases the water’s contact with air, oxidizing the iron and manganese. The water then flows by gravity to a 136,000-gallon detention tank and is held for approximately 30 minutes. At this point, potassium permanganate is added to further oxidize whatever doesn’t get oxidized by aeration and detention. Aadalen says they also add manganese sulfate at this point. “We have pretty low entry levels of manganese, so we add that partially because if we added too much potassium permanganate it might get into pink-water troubles. Also, it optimizes, it forms hydrous manganous oxides (HMOs), so it’s part of the treatment process that helps for radium removal.”

Filtration is next. Each plant has four filter cells. The cells are 20 x 20 feet at Twin Bluffs and 18 x 18 at Charlson Crest and contain 15 inches of anthracite on top of 15 inches of manganese greensand. Aadalen says the process is “basic iron-manganese technology, which is how we remove the radium. Greensand can physically filter out the manganese, which the radium is adhered to. The radium adheres to the manganese, and we can physically remove the manganese, and the radium just sticks to it.”

Backwashing occurs after approximately five million gallons of water have been filtered at Twin Bluffs and four million gallons at Charlson Crest although Aadalen says they will always backwash at least once a week to recharge the greensand. The clear water is reclaimed and pumped through the filters again while the sludge goes to the wastewater plant. The backwash reclamation process can recover up to 90 percent of the water.

|

|

Above: Corey Aadelen in the plant’s laboratory. Below: Water is held approximately 30 minutes in a 136,000 gallon detention tank. |

|

Distribution

The distribution system has seven elevated reservoirs and one ground-storage reservoir for a capacity of six million gallons and five separate pressure zones: low, intermediate, two western-intermediate zones, and high.

When the clearwell is full, water flows by gravity to a one-million gallon ground-storage reservoir at Booster Station 7, where it is pumped into the low and intermediate systems. Water from the Charlson Crest plant is pumped into the low system. Chlorine and ammonia are added to form a residual disinfectant at both the Charlson Crest plant and Booster Station 7.

Pump stations around the city take water from the low and intermediate systems and transfer it to the two western intermediate levels and the high level.

Controls

Programmable logic controllers (PLC) are used with the wells, treatment plants, and pumps, allowing operators to control the plant on site or remotely from a laptop computer. The PLC activates an automatic dialing system if there is a problem, and operators can respond either at the plant or from their laptop computer.

Results

The new plants have been successful in reducing the levels of radionuclides. Treated water results show levels of under 1 pCi/L for radium 226, under 3 pCi/L for radium 228, and under 3 pCi/L for gross alpha emitters. In addition, Aadalen says they are receiving no complaints about iron.

Besides Aadalen, the treatment plants, reservoirs, and pump stations are staffed by two certified operators, Gerry Butenhoff and Ed Krawiecki.