Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Shoreview Thrives with New Water Treatment Plant

From the Summer 2017 Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

Shoreview is a suburb in the northern Twin Cities with approximately 26,000 residents and has been ranked by Family Circle magazine as one of the best cities for families. The city grew rapidly in the 1970s and 1980s, residentially and commercially, but focus has shifted from new development to infill and redevelopment. The city has a number of large employers and a stable tax base.

Its water utility provides approximately 3 million gallons a day (MGD) of safe drinking water to its citizens and businesses and, until recently, did not have a water treatment plant. Shoreview had operated a water supply system consisting of six wells, raw-water transmission piping, a storage reservoir, chemical feed systems, and a booster pump station. It served the city well for decades, but increasing color-related concerns and aging infrastructure prompted the city to hire Advanced Engineering and Environmental Services, Inc. (AE2S) of Maple Grove, Minnesota, to design an 8 MGD filtration plant to remove iron and manganese.

Manganese, which can discolor the water, was the main motivator for the plant, according to utilities supervisor Kevin Chmielewski, who said that manganese levels had been rising and causing more customer complaints. The objectives established for the new treatment plant included ammonia removal, iron and manganese removal, hydrogen sulfide removal, radon removal, fluoridation, disinfection, a protective disinfectant residual in the distribution system, and disinfectant by-product control.

Options Evaluated and Treatment Process Selected

With objectives determined, the city worked with AE2S to evaluate several alternative technologies and conduct a pilot study evaluating greensand filtration and alternative oxidation processes. Chmielewski added that the new treatment process positions the city to meet future regulations that could become part of the federal Safe Drinking Water Act.

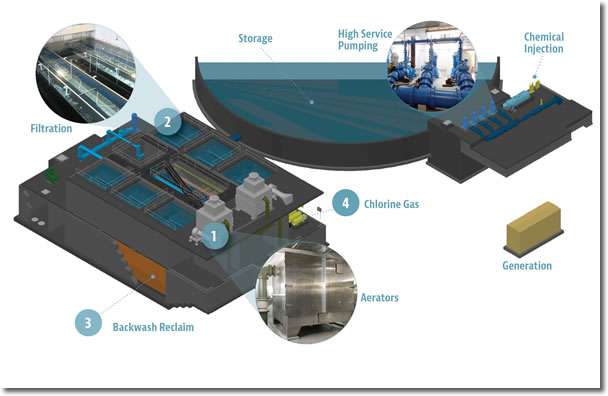

The treatment process (shown below) consists of:

-

Two forced draft aerators for preliminary oxidation to the iron and manganese as well as to release any dissolved gases in the water; the aeration also limits the amount of chlorine needed.

-

Six dual-sand filters (greensand and anthracite) to remove any manganese after aeration.

-

Backwash reclaim, which sends the backwash water from the filters to a pair of 215,000-gallon-reclaim basins, where the iron and manganese that have been removed are settled out. The rest of the water is suctioned from the top of the basins back to the treatment process, reducing waste.

-

Chlorine gas to provide primary disinfection and oxidation of the iron and manganese. Following treatment, chlorine and fluoride are added.

Construction

Construction began in June of 2015, and the treatment plant was on-line by the end of October of 2016. When the new water treatment plant came on line, Shoreview’s distribution system needed to be flushed to minimize water quality complaints. The flushing strategy was developed through use of the city’s distribution system model to determine the most efficient flushing method and anticipate the required amount of time to flush the system.

With the help of AE2S, the city alerted its citizens of the change and what to expect during the flushing process. Chmielewski’s prior experience working at the city of Circle Pines, another northern suburb, in the 1990s taught him the value of upfront communications.

It took time for the community and Shoreview’s operators to become comfortable with the improved disinfection strategy. Their previous chloramine disinfection strategy used the naturally occurring ammonia in the water and combined it with chlorine to create a chloramine disinfectant. Shoreview’s ability to create this chloramine disinfectant was restricted by the amount of naturally occurring ammonia in the raw water. The new plant produces additional disinfectant that allows for an extended reach in their system. This additional disinfection strength provides safer water to its residents. The distribution system also acclimated to the new disinfection strategy, allowing for a more stable residual over time.

The plant is on the north side of Minn. Hwy. 96, just to the east of Victoria Street, a location chosen for flexibility and future growth. There is sufficient room to expand, if needed, to twice its size by adding a mirror image of the existing plant to the south side of the clearwell.

Due to the location and visibility of the new site, the city considered its curbside appeal and how it fit into the community. Not only does the exterior brick match surrounding buildings, the filter rooms were built to include decorative lights that turn from dark blue to light blue during the day or red and green during the holidays. The lights shine through the windows and make the building a positive addition to the area.

The water treatment plant features attractive wooden ceilings.

As for financing the new plant, the city of Shoreview took a progressive approach to infrastructure funding and leads as an example in the metro area in the practice of responsible planning and budgeting for capital improvements projects. The $10.4 million project was financed through the municipal bond program and pro-active water rate planning.

So far the response has been positive from residents. Their questions have been answered and their concerns were addressed throughout the whole process. Now that the system is fully operational the residents are grateful for a safe and stable water source.

Chmielewski said,, "I'm happy to have been part of a project that will make such a big impact on our community."

|

| Construction on the new water treatment plant in Shoreview began in June 2015 and was completed in October 2016. |

|

Of Interest

Pumphouses Designed for Function as Well as Attractiveness

Hastings Removes Nitrate with New Plant

Go to > top