Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Waite Park Uses Air Strippers to Restore “Lots and Lots” of Good Water

From the Winter 2009-2010 Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

The city of Waite Park has used air stripping to remove volatile organic chemicals from the water since 1988. In the foreground is the original plant, with one tower. A new plant, to the left, went on-line in the early 2000s, with two air stripping towers.

The central Minnesota city of Waite Park, on the western edge of St. Cloud, sits atop a quaternary water table and buried artesian aquifer that provides “lots and lots” of good water, according to waterworks employee Dale Warzecha. “If it wasn’t for what man did to it,” he says, “the good Lord put some good stuff in there.”

However, beginning in the 1890s, railroad shops and factories were constructed in the northern part of the city. Using accepted disposal practices of the time, the industries went about their business with no one realizing the impact on the city’s water supply.

Nearly 100 years later, volatile organic chemicals (VOCs)—specifically trichloroethylene and tetrachloroethylene—turned up in the water at elevated levels. For a short-term fix, the city took Wells 1 and 3, which are located near the railroad property, out of service and relied on Well 2, which was located in another part of the city. Waite Park also purchased water from St. Cloud while looking for a solution.

|

| The water treatment plant in Waite Park has two air stripping towers and a gravity filter with four cells. |

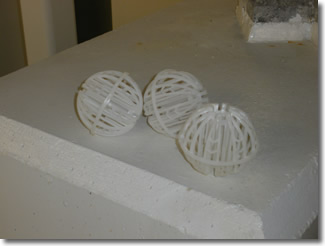

That solution turned out to be aeration, which is effective in removing chemicals that evaporate easily, such as solvents and fuels. Waite Park built its first treatment plant, which was completed in 1988, between Wells 1 and 3. The plant had one air stripping tower, with the packing consisting of aeration balls, about the size and somewhat similar in resemblance to wiffle balls. In addition to aeration oxidizing the volatile organic chemicals, the process also oxidized iron and manganese, thereby improving the aesthetic qualities of the water.

Warzecha noted some special challenges they experienced with the plant. Oxidation from the stripping process raised the pH of the water, causing minerals to precipitate and foul the media. As a result, water channeled through the foul balls without the proper aeration, and the balls had to be replaced.

|

| The air stripping towers are packed with hollow balls to remove contaminants. The photo at right shows fouled balls coming out of the air stripping tower in the original plant, which is no longer in service. |

Well 4, a few hundred feet to the east, went into service in the early 1990s to deal with the city’s growth. The plant was designed for only 800,000 gallons per day, but, because of demand, was being pushed to 1.2 million gallons per day at times.

Planning began in the late 1990s for a new plant to increase capacity to match the new development and growth taking place in Waite Park. “We learned a lot from the [old] plant in designing the new one,” said Warzecha. One of the lessons was to add a second aeration tower to provide for redundancy in the plant. Another was to add CO2 in the towers to lower the pH to prevent fouling of the media.

|

| Wells 1 and 3 are in back of the old plant (left). Photo at right shows the base of the air strippers in the existing treatment plant. |

The new plant was designed for 3.6 MGD, and, to match plant capacity with well capacity, a new well went into service at the same time the plant went on-line.

Water entering the plant goes first to one of the two strippers (which alternate daily) for aeration and then into a detention tank, where the CO2 and water combine. Potassium permanganate is also added for iron and manganese removal before the water moves into the filter cells.

Waite Park now has approximately 6,700 residents, and the treatment facility puts the utility in position to handle future demand. To date, at its peak, the plant has reached only half its capacity, leaving plenty of capacity for potential growth in the city.

|

| Atop the stripping towers, a look at the old plant (left). In the photo to the right, Minnesota Department of Health engineer Jon Groethe is in the foreground; Dale Warzecha and Dale Marthaler of Waite Park are in the background. |