Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Waterline: Spring 2018

Editor:

Stew Thornley

Subscribe to The Waterline newsletter. An e-mail notice is sent out each quarter when a new edition is posted to the web site.

On this page:

- Water Bar Opens New Storefront

- Golden Valley Survives Contractor Accident without Water Disruption

- Banat Retires from MDH; Blair to Succeed Hubbard at MRWA

- Johnson and Larsen Named MDH District Engineer Supervisors

- Community Commitment Results in Innovative Water Plant in St. Martin

- The Latest on Lewis & Clark

- Densa

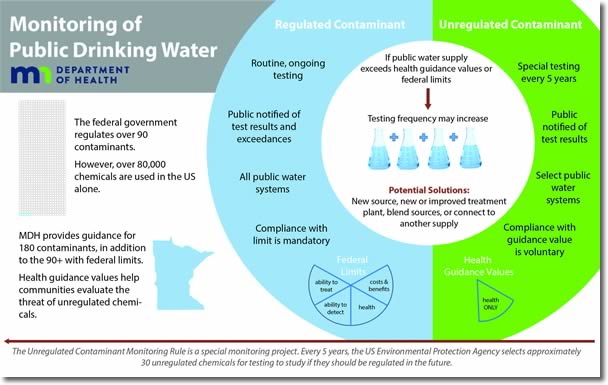

- Unregulated Contaminant Monitoring Rule 4 (UCMR 4) Is Here

- Waterline Survey Results

- Even More Words to Live By

- Densa Answers

- Reminder to All Water Operators

- Calendar

Water Bar Opens New Storefront

Water Bar—a combination of water, art, and social infrastructure that has been a hit across the state—has opened a new storefront at 2518 Central Avenue NE in Minneapolis. With watertenders serving water from various cities, Water Bar has been on site in many locations, including the State Fair and the annual conference of the Minnesota Section of American Water Works Association. With a permanent location, Water Bar is now open every Saturday. As visitors sip the water, they’re treated to artwork and ecology displays within the studio. Water professionals from around the state are invited to bring their water and tell the story behind it while serving a shift as a watertender at Water Bar.

Go to top

Golden Valley Survives Contractor Accident without Water Disruption

A watermain break caused by a construction accident in Golden Valley threatened services to Regency Hospital last fall. The break occurred Monday morning, November 13, 2017 when a contractor punctured an 18-inch concrete pipe while installing a water line for snowmaking equipment at nearby Theodore Wirth Park.

A watermain break caused by a construction accident in Golden Valley threatened services to Regency Hospital last fall. The break occurred Monday morning, November 13, 2017 when a contractor punctured an 18-inch concrete pipe while installing a water line for snowmaking equipment at nearby Theodore Wirth Park.

Golden Valley water superintendent Joe Hansen said the hospital was the only customer between the two 18-inch valves where the damage occurred. In between is a 6-inch valve, which the city used to continue to supply the hospital with water as it constructed a bypass pipe. Staying in touch with Minnesota Department of Health (MDH) engineer Brian Noma and others, city crews constantly monitored pressure in the basement of the hospital. Hansen said the pressure stayed between 30 and 40 pounds per square inch, well above levels that could cause a concern regarding backflow.

The city completed the temporary service the same day, disinfected the pipe, and sampled the water. The results, which came back the next day, were good, and the water was turned on. However, some type of water hammer occurred, bursting the pipe and requiring another round of disinfecting and sampling. It wasn’t until Wednesday when the city could begin operating the bypass.

Hansen said they only throttled down the 6-inch valve, rather than risking any negative pressure by turning it off completely, as they began repairs on the primary main on Friday morning. Since the hole was dug and the pipe was exposed under pressure, there was no need to send a sample off to the lab for a bacteria sample, as long as the section of new pipe and fittings were disinfected. The city flushed the main, tested for chlorine residual Friday night, and was able to resume its normal supply to the hospital.

A drinking water advisory for a hospital could cause a major problem, but the city was able to keep the water flowing, and Regency Hospital was able to continue operating in normal fashion.

Fortunately, because of the response of city utility workers, hospital staff, and others, Golden Valley and Regency Hospital were able to fix a serious situation caused by a private party without disrupting service.

Go to top

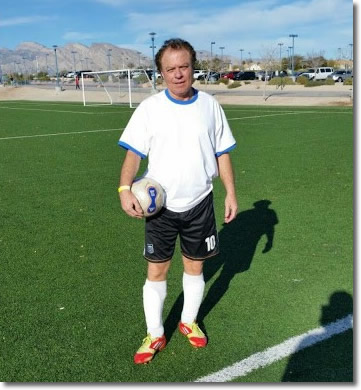

Banat Retires from MDH; Blair to Succeed Hubbard at MRWA

Bassam Banat has retired after 32 years and 4 months with the Minnesota Department of Health (MDH). Born in Beirut, he began playing soccer professionally when he was 17 and made it to the highest level on the Lebanon Premier team. He also played two years in the United Arab Emirates. Banat came to the United States December 22, 1975 at the age of 23. He eventually made his way to Grand Forks to study civil engineering at the University of North Dakota, where he was the captain of a club soccer team. After college he worked as a civil engineer in Abu Dhabi in the United Arab Emirates from 1981 to 1985. Banat, married to Becky by this time, returned to the U. S. and applied for jobs. He was hired by Gary Englund to begin work at MDH on September 9, 1985.

Bassam Banat has retired after 32 years and 4 months with the Minnesota Department of Health (MDH). Born in Beirut, he began playing soccer professionally when he was 17 and made it to the highest level on the Lebanon Premier team. He also played two years in the United Arab Emirates. Banat came to the United States December 22, 1975 at the age of 23. He eventually made his way to Grand Forks to study civil engineering at the University of North Dakota, where he was the captain of a club soccer team. After college he worked as a civil engineer in Abu Dhabi in the United Arab Emirates from 1981 to 1985. Banat, married to Becky by this time, returned to the U. S. and applied for jobs. He was hired by Gary Englund to begin work at MDH on September 9, 1985.

Ruth Hubbard (known as “Ruthie” by friends) is retiring after nearly 35 years with the Minnesota Rural Water Association (MRWA), the last 22 as the administrator/executive director. A native of Elbow Lake, where the MRWA office is located, she began in 1983 at the time the office was moved from Slayton to Elbow Lake. Sam Wade and Chuck Anderson were her only two co-workers at the time, and MRWA now has 17 staff members and has grown from approximately 50 to more than 950 members. The annual technical conference, which is still held in the same location in St. Cloud, began in 1983 and was so small they were able to hold it poolside.

Ruth Hubbard (known as “Ruthie” by friends) is retiring after nearly 35 years with the Minnesota Rural Water Association (MRWA), the last 22 as the administrator/executive director. A native of Elbow Lake, where the MRWA office is located, she began in 1983 at the time the office was moved from Slayton to Elbow Lake. Sam Wade and Chuck Anderson were her only two co-workers at the time, and MRWA now has 17 staff members and has grown from approximately 50 to more than 950 members. The annual technical conference, which is still held in the same location in St. Cloud, began in 1983 and was so small they were able to hold it poolside.

Succeeding Hubbard is Lori Blair, who has worked at MRWA for 18 years, most recently as information specialist. A native of Iowa, Blair got her Bachelor of Science degree in business administration from Southwest Minnesota State University in Marshall. Blair’s husband, Brian, works for the Minnesota Department of Transportation. Lori and Brian have two daughters, Alyssa and Ashton, who are in college, as well as a dog, Duke, and a cat, Lucky.

Succeeding Hubbard is Lori Blair, who has worked at MRWA for 18 years, most recently as information specialist. A native of Iowa, Blair got her Bachelor of Science degree in business administration from Southwest Minnesota State University in Marshall. Blair’s husband, Brian, works for the Minnesota Department of Transportation. Lori and Brian have two daughters, Alyssa and Ashton, who are in college, as well as a dog, Duke, and a cat, Lucky.

Johnson and Larsen Named MDH District Engineer Supervisors

Todd Johnson and Kim Larsen have been named district engineer supervisors for the Minnesota Department of Health, succeeding long-time engineers/supervisors Dave Schultz, Steve Pederson, and Mark Sweers, who retired in 2017.

Beyond supervising district engineers, Johnson will be responsible for managing issues related to contaminants of emerging concern and special sampling (such as the Unregulated Contaminant Monitoring Rule). He will also serve as the primary technical lead for communications.

Larsen, the other district engineer supervisor, maintains other responsibilities that include emergency preparedness and response (working with security engineer Jon Groethe), Legionella management and response, and cross-connection control.

Go to top

Community Commitment Results in Innovative Water Plant in St. Martin

One of the newest water treatment facilities in Minnesota is also one of the first engineered biological water treatment plants in the state. Some other cities, such as Hutchinson, have partial biological treatment; however, St. Martin, a community of 343 people in central Minnesota, stands out with an entirely engineered biological plant.

Beyond the innovation in the plant is the strong community involvement in the project. Minnesota Department of Health (MDH) engineer Kim Larsen credits city clerk Cara Olmscheid, St. Martin’s only full-time employee, for her commitment to the project. Olmscheid, who notes that “city clerks have to wear many hats,” is knowledgeable about and involved in the water system in addition to the other duties she carries out each day.

Olmscheid recognizes the support of James “Boots” Rothstein, a colorful native of St. Martin who has been mayor since 2002. Rothstein spent 35 years in New York, working for Chase Manhattan Bank, operating a restaurant, and serving 12 years as a detective for the New York Police Department, working undercover to infiltrate prostitution and pedophilia rings. Rothstein returned to his hometown to assist his aging parents and has also been active in combating human trafficking in the area.

Rothstein was president of the Sauk River Watershed District and, as mayor, the primary proponent in initiating the water project, according to Olmscheid. “As others sat back and talked about the cost, the mayor said, ‘We have to have good water.’”

|

|

Above: Dave Schaaf of the Minnesota Department of Health, Dave Schultz of WSB & Associates, and Boots Rothstein, mayor of St. Martin. Below: The biological iron filter, the first of the chain of three filters. |

|

Sources

The city had been operating with two shallow wells (1 and 2), which had benzene levels above the maximum contaminant level (MCL). The Minnesota Pollution Control Agency (MPCA) installed filters at the wells that dropped the benzene to below detectable levels.

Olmscheid said in 2006 they discovered a hole in the casing of Well 1, prompting its sealing and the drilling of a new well (Well 3) next to it. The wells were near a creek and considered vulnerable to contamination. In 2011, the city found a hole in the casing of Well 2, and took it out of service, leaving St. Martin with only one well.

Meanwhile, Rich Soule of the MDH Source Water Protection Unit came to St. Martin and expressed concern about the location of Wells 2 and 3, especially since the creek that was the outfall of the wastewater treatment plant, which had a history of petroleum release. Because of the MPCA filters, Soule said, “There was no screaming need to get something done, but there was a concern, especially with two wells in the same aquifer,” adding, “Don’t put your eggs in one basket.”

The geology of the area is underlain with a granite shelf, making it difficult to find sites with a sufficient yield within the city limits, so St. Martin drilled two new wells to the east of the city.

Larsen said the current wells are considered nonvulnerable, in contrast to the shallow wells by the creek. However, high levels of iron and manganese in the ground caused aesthetic concerns, especially with the staining of fixtures in people’s homes. “It was awful,” said Olmscheid. In addition, high levels of ammonia are present in the new wells, although not as high as they had been in the previous ones.

During this period, St. Martin was meeting with the U. S. Department of Agriculture (USDA) Rural Development regarding its wastewater and found out that rates that they qualified for, based on per-capita income, could be carried over to a water system.

St. Martin explored its options, worked with MDH, USDA, Tonka Water of Plymouth, Minnesota, and WSB & Associates, Inc. of St. Cloud, and settled on biological treatment, using naturally occurring bacteria instead of chemicals to remove contaminants. The city leased a trailer to do a pilot study, which was set up by Tonka Water and WSB & Associates, and city staff did the daily testing and pilot work. Olmscheid said they performed the studies for four months, wanting to make sure the innovative technology would work.

"It's more important to make sure it's done right

than it is to meet the deadline."

—Mayor Boots Rothstein

Treatment Process

The plant has three vessels. The first is a biological iron filter, which receives the water after air has been added to facilitate the biological oxidation of iron.

More air is then injected to facilitate the biological conversion of ammonia to nitrite and then to nitrate. “We’re not feeding any organisms,” said Dave Schultz of WSB & Associates, “just creating a robust environment for the natural bugs to grow biologically and convert the ammonia, letting nature do the work.”

The second vessel is an ammonia nitrification filter, in which two reactions occur. The first, the oxidation of ammonia to nitrite, is by the nitrosomonas genus bacteria. The next is by the nitrobacter genus to convert the nitrite to nitrate.

Oxidized manganese and any remaining biological matter are filtered with anthracite and greensand in the third vessel.

After filtration, three chemicals are added: fluoride for dental care, chlorine for disinfection and to maintain a residual in the distribution system, and a corrosion-control inhibitor.The filters are backwashed with non-chlorinated water from a concrete backwash holding tank in order to not disrupt the bio-growth on the filter media.

Construction began in July 2016, and the total project cost just more than $3 million, which included the plant and related infrastructure. Approximately 45 percent of the amount came from a grant and the rest from a 40-year load at an interest rate of 1.875 percent, both from USDA Rural Development.

Asset Management

St. Martin has been forward-looking in other ways, according to Larsen, who pointed out that most small cities with only one full-time clerk and a few operators do not have the time and resources to develop an asset management plan. “St. Martin has spent many years focused on the future of the water system.” Utilities, typically larger ones, use asset management to maintain their infrastructure in a controlled and planned manner, to set water rates in a way to offset the need for loans, and to keep operating without disruption.

A detailed list of assets—wells, valves, meters, storage facilities, pipes, and service lines—helps cities develop a plan on how to maintain and/or replace them and to head off emergency situations that may disrupt service and cause unexpected expenses. “St. Martin has good information because the city clerk [Olmscheid] has an excellent understanding of the importance of infrastructure. She enjoys solving problems, getting funding, and seeking to better the town. And [she’s] not afraid to spend money. The person or persons in charge of the checkbook are critical drivers in having a CIP [capital improvement plan] or asset plan.”

The new treatment plant went on-line in September 2017. Larsen credits Olmscheid and other city leaders for their commitment to the water system.

“We were keying on this because of the community involvement,” said Larsen. “Everyone was so excited about it. That’s terrific.”

The Minnesota Department of Health worked with the city on a video of the new treatment plant:

Other Invisible Heroes videos:

- Invisible Heroes: Fairmont

- Invisible Heroes: New Brighton

- Invisible Heroes: Worthington

- Invisible Heroes: Oakdale

- Invisible Heroes: St. Cloud

Go to top

The Latest on Lewis & Clark

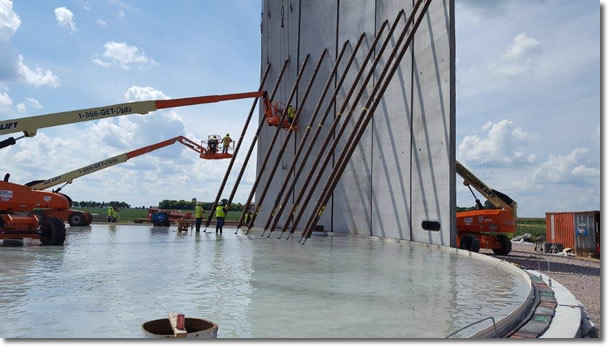

Wall panels are installed for the Rock County reservoir.

The Lewis & Clark Rural Water System connected to Lincoln-Pipestone Rural Water System (LPRWS) in November, making the system the 14th of 20 partners to be connected. The water started flowing upon completion of construction by LPRWS of over 20 miles of pipeline between Edgerton and Magnolia, the first of two connections for LPRWS, which serves a wide area that includes 38 cities in 10 Minnesota counties.

Conceived in 1988 as a way of serving water-challenged areas in South Dakota, Iowa, and Minnesota, the Lewis & Clark project takes water from a series of wells that tap into an aquifer adjacent to the Missouri River near Vermillion, South Dakota. The water is delivered to communities as far away as 125 miles.

The water first reached Minnesota in 2015, reaching Rock County Rural Water District. Since then, Luverne and Magnolia have also been connected. The water has allowed Luverne to be the site of Minnesota’s first shrimp hatchery and harbor, a commercial-scale shrimp producer.

Next up is to extend the pipes to east of Adrian, another connection point to Lincoln-Pipestone, and then to Worthington.

Foundation work for the pump station in Worthington, which is expected to be connected to the Lewis & Clark Rural Water System by the end of 2018.

Go to top

Densa

Are you smart enough to join Densa? Give it a shot:

1. Some months have 31 days; how many have 28?

2. In baseball, how many outs are in an inning?

3. Can a man in California legally marry his widow’s sister?

4. Divide 30 by 1/2 and add 10. What is the answer?

5. If there are 3 apples and you take away 2, how many do you have?

6. A farmer has 17 sheep standing in a field and all but 9 drop down and die, how many sheep are still standing?

7. How many two-cent stamps are there in a dozen?

8. Haywood’s mother had three children. The first child was named April. The second child was named May. What was the third child’s name?

Go to top

Unregulated Contaminant Monitoring Rule 4 (UCMR 4) Is Here

By Anna Arkin, Minnesota Department of Health

What is UCMR 4?

Every five years, the U.S. Environmental Protection Agency (EPA) implements the Unregulated Contaminant Monitoring Rule (UCMR) to collect data on contaminants that may be present in drinking water. The fourth round of UCMR, UCMR 4, requires monitoring for 30 contaminants between 2018 and 2020. The contaminants include 2 metals, 9 pesticides, 3 alcohols, 3 semi-volatiles, 3 brominated haloacetic-acid groups, 2 disinfection by-product indicators, and, for surface water systems, 10 cyanotoxins.

These contaminants are not regulated under the Safe Drinking Water Act. EPA collects results from across the country and decides if the contaminants occur at frequencies and concentrations high enough to be regulated.

More information is available at EPA’s Fourth Unregulated Contaminant Monitoring Rule.

Click on image to enlarge

Which systems are included?

UCMR 4 includes all public water systems (PWSs) serving more than 10,000 people and some small water systems serving 10,000 or fewer people. If your system is included, you were notified by MDH in 2017.

What is the timeline for sampling and data reporting?

Sampling started in January 2018 and will end in December 2020. Groundwater systems will monitor twice, five to seven months apart. Surface water systems will monitor four times, three months apart (quarterly).

The Minnesota Department of Health (MDH) will send results to participating PWSs as they become available.

What is MDH’s role?

MDH, as it does with most regulated contaminant monitoring, will:

- assume responsibility for sample collection. Your MDH district engineers will be collecting the samples.

- pay for sample analyses using the MDH Service Connection Fee fund. (EPA will pay for sample analyses for small PWSs.)

- ensure results are reported to the EPA and the primary contact at participating PWSs.

What is the PWS’s role?

EPA requires PWSs to report unregulated contaminants detected during UCMR monitoring in the Consumer Confidence Report (CCR) following the year they were detected. MDH will include UCMR4 detections in the CCR template we provide to your PWS. If your system wants to provide additional information to consumers, MDH technical staff are available as a resource.

Are there standards for UCMR 4 contaminants?

Because the contaminants being tested are unregulated, no federal standards for them exist. However, there is human health effects information available for some of the UCMR 4 contaminants:

- EPA’s Drinking Water Contaminant Human Health Effects Information

- MDH’s Guidance Values and Standards for Contaminants in Drinking Water

If you have any questions, please contact Todd Johnson at 218-308-2110 or Cindy Swanson at 651-201-4656. We will provide updates as the UCMR 4 process continues over the next two years.

Go to top

Waterline Survey Results

Thank you to the many readers who took the time to provide feedback by responding to the survey that was in the Winter 2017-2018 Waterline. Here is the summary:

| How much of the Waterline do you read? | All of it | Some of it | None of it |

| 56.1 percent | 43.9 percent | 0 | |

| What is your impression of the Waterline? | Excellent | Good | Needs work |

| 69 percent | 27 percent | 4 percent | |

| How often do you read these articles? | Frequently | Occasionally | Not at all |

| Feature articles (such as the St. Martin story) | 84.3 percent | 15.7 percent | 0 |

| Regulatory and compliance information | 44.9 percent | 47.1 percent | 8 percent |

| Human interest stories | 52.5 percent | 47.5 percent | 0 |

| Minnesota AWWA news | 52.3 percent | 39.7 percent | 8 percent |

| Operator training news | 64.2 percent | 24.8 percent | 12 percent |

Here is a smattering of comments made for suggestions for other articles and sections that could be added:

Upcoming school opportunities. Better description of courses.

I prefer shorter articles that can be read quickly.

I think that the quality of your articles, and the subject matter presented is overall very good quality.

Keep up the effort to present articles from outstate. We are not all living or working in the Cities. More photos.

Community stories like the Blaine article are an excellent learning resource.

It is a good publication as is.

Go to top

Even More Words to Live By

No one wants advice—only corroboration

—John Steinbeck

I’d give my right arm to be ambidextrous.

—former pitcher Dick Pole

Never miss a good chance to shut up.

—Robert Benchley

When your work speaks for itself, don’t interrupt.

—Henry J. Kaiser

Go to top

Densa Answers

1. 12

2. 6

3. No (There is no precedent for a dead man to marry)

4. 70

5. 2

6. 9

7. 12

8. Haywood

Go to top

Reminder to All Water Operators

When submitting water samples for analyses, remember to do the following:

- Take coliform samples on the distribution system, not at the wells or entry points.

- Write the Date Collected, Time Collected, and Collector’s Name on the lab form.

- Sign the form where it says "Relinquished by."

- Write the Sample Point on lab forms for bacteriological and fluoride samples.

- Attach the label to each bottle (do not attach labels to the lab form).

- Include lab forms with submitted samples.

- Do not use a rollerball or gel pen; the ink may run.

- Consult your monitoring plan(s) prior to collecting required compliance samples.

Notify your Minnesota Department of Health district engineer of any e-mail changes for contact people.

If you have questions, call the Minnesota Department of Health contact on the back of all sample instruction forms.

Calendar

Operator training sponsored by the Minnesota Department of Health and the Minnesota AWWA will be held in several locations this spring.

Register for schools and pay on-line:

Go to top