Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Waterline: Summer 2019

Editor:

Stew Thornley

Subscribe to The Waterline newsletter. An e-mail notice is sent out each quarter when a new edition is posted to the web site.

On this page:

- Cities Work Together to Conquer Water Issues

- Lewis & Clark Completed in Minnesota but Work Is Everlasting

- Operator Protection and Disposal Guidelines for Spent Media or Backwash Waste Containing Radium

- Taste Test at MRWA Conference

- EPA Develops PFAS Action Plan

- Freeborn and Hartland Collaborate for Shared Water System

- MDH Issues New Home Water Treatment Fact Sheet

- Metro School Draws Big Crowd

- Resilience Planning and Adaptation Training for the Water Utility Sector

- Minnesota Rural Water Association Lead Service Line Survey

- Metropolitan Council Honors Employees for Drinking Water Awards

- Eden Prairie Reservoir and Pumphouse to Replicate and Recognize History

- MDH Guidance to Operator Exposure to Radon at Water Treatment Plants

- Promote Water Careers in Consumer Confidence Reports

- Complying with America's Water Infrastructure Act

- Past Waterlines Archived at wateroperator.org

- Words to Live By

- Reminder to All Water Operators

- Calendar

Cities Work Together to Conquer Water Issues

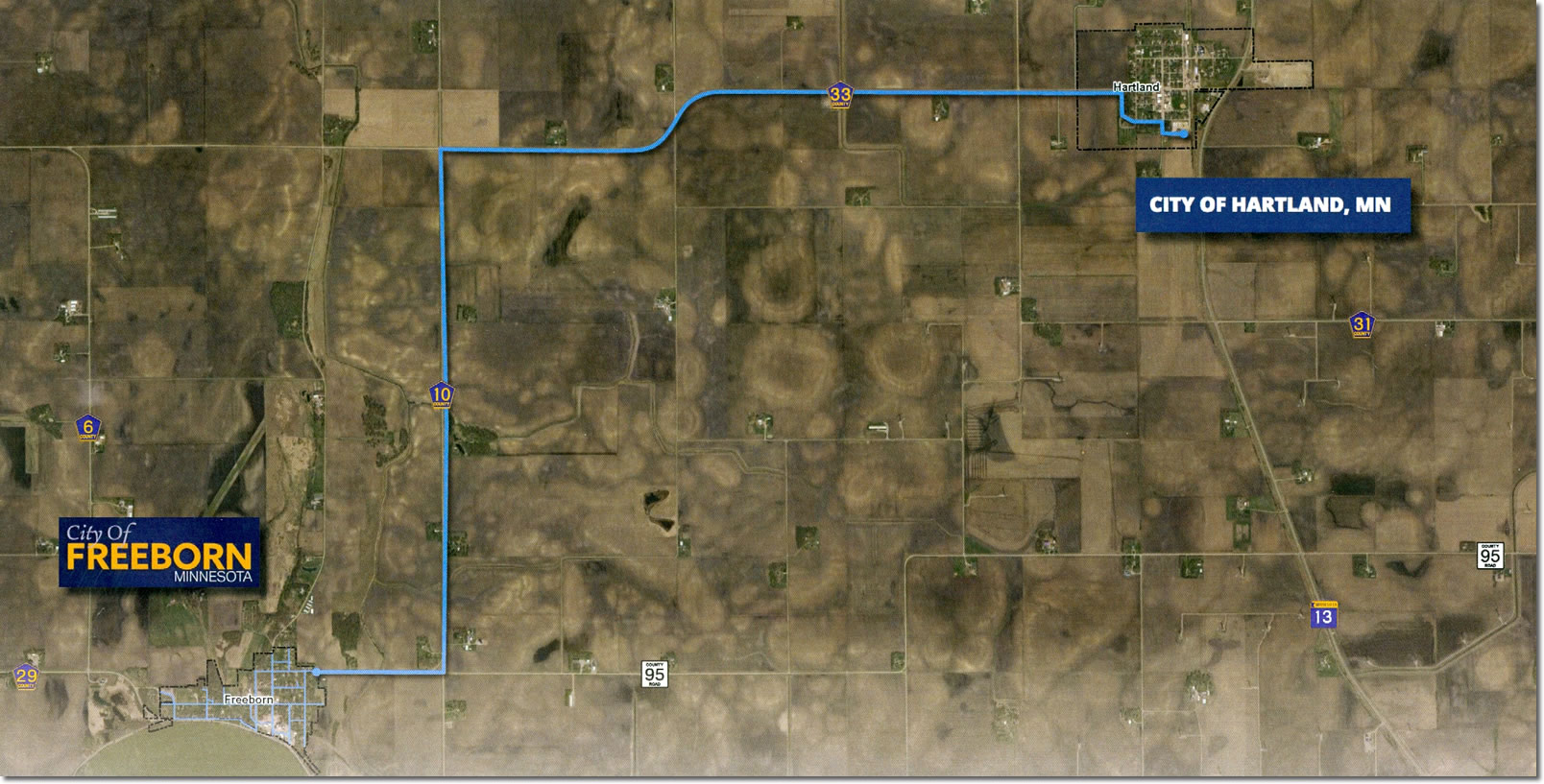

Two cities: one water plant. That’s how Freeborn and Hartland worked together to deal with separate water issues, save money, and serve their communities. (Click on the image above to enlarge it; click on it a second time to enlarge it even more.)

Go to top

Lewis & Clark Completed in Minnesota but Work Is Everlasting

The Lewis & Clark Rural Water Project was completed in Minnesota in late 2018 although work continues. Leak location and repair on a 15-mile segment of PVC pipe from Adrian to Worthington was done over the winter. Weather and deep frost, in addition to the tiny nature of some of the leaks, made the locating challenging. S. J. Louis Construction, Inc. of Rockville, Minnesota, used green dye mixed into the water when filling some sections of the pipe. The dye differentiated water from the pipe and groundwater when digging up the joints. In the photo, a previous leak repair was being removed to install caps and shorten the length of pipes being searched for leaks. Conceived in 1988 as a way of serving water-challenged areas in South Dakota, Iowa, and Minnesota, Lewis & Clark takes water from a series of wells from an aquifer adjacent to the Missouri River near Vermillion, South Dakota, and delivers it to communities as far away as 125 miles.

Go to top

Operator Protection and Disposal Guidelines for Spent Media or Backwash Waste Containing Radium

When filter media or backwash waste containing radium needs to be handled by personnel at the water treatment facility, personal protective equipment, such as gloves and masks, should be used to minimize exposure to radiation. While radiation at water treatment facilities is not likely to pose an acute risk, prolonged exposure at low doses may increase the risk of cancer. Personal clothing that comes in contact with filter media needs to be laundered before the employee returns home. Skin that comes in contact with filter media should be washed thoroughly, particularly before eating.

Waste that is sent to a landfill or is land applied must be tested and handled in accordance with the Minnesota Pollution Control Agency guidance document. The entity that generates the waste is responsible for determining the type of waste it is and ensuring proper disposal.

For disposal in unlined landfills, radium-226 cannot exceed 5 picocuries per gram (pCi/g). For lined landfills, the radium-226 concentrations cannot exceed 30 pCi/g. For radium concentration greater than the limits, it is possible to dilute the media or filter backwash by mixing it with low-radioactivity material. Otherwise, disposal of materials greater than these limits may require a specialized landfill permitted for radioactive materials.

Go to top

Taste Test at MRWA Conference

Anita Smith of the Minnesota Department of Health, Kirk Peterson of Core & Main, and Carmelita Nelson of the Minnesota Department of Natural Resources were judges for the taste test, won by the city of Saint Peter, at the Minnesota Rural Water Association Technical Conference in St. Cloud in March.

Go to top

EPA Develops PFAS Action Plan

The U. S. Environmental Protection Agency (EPA) has outlined steps it is taking to address Per- and Polyfluoroalkyl Substances (PFAS).

The actions include short-term solutions and long-term strategies to address the issues along with a national research and risk-communication plan and a response to the public input the EPA has received from the PFAS National Leadership Summit.

EPA is also moving forward with the process to develop a maximum contaminant level for some of the most prevalent chemicals in the PFAS class.

Go to top

Freeborn and Hartland Collaborate for Shared Water System

The southern Minnesota cities of Freeborn and Hartland are six miles apart and have faced different challenges with their drinking water, the former with arsenic and the latter with radium.

Hartland (home of humorist Al Batt) operated with a 1973 treatment plant that had never undergone any major renovations. According to Jake Pichelmann of Bolton & Menk, Inc. of Mankato, Minnesota, the chemical feed system was in poor condition, the electrical and controls equipment were obsolete, and the steel gravity filter leaked. Water/wastewater superintendent Andy Flatness said they used sandbags to direct water from the leaky filter to the floor drains. “The old plant was failing,” he said, “not pulling iron and manganese out like it should.” The plant was also not equipped to deal with rising radium levels.

Hartland’s 1959 well had sand issues and was being used as a backup, leaving only a 1992 well, which had corrosion and was in need of casing repairs.

Freeborn, which does not have a treatment plant, drew water from a pair of 1950s wells that were nearing the end of their life span. Its distribution system of 4-to-6 inch cast-iron pipe was in poor condition, and the city had experienced 12 main breaks within 5 years. “We needed to do something,” said water/wastewater superintendent Bill Guggisberg. Since it was exceeding the maximum contaminant level (MCL) for arsenic, the city had been operating with a compliance agreement with the Minnesota Department of Health (MDH).

| ||

| Bill Guggisberg and Andy Flatness stand next to a pipe that sends water to their cities—Freeborn to the left and Hartland to the right. | ||

|

Exploring a partnership, Guggisberg said they looked in different directions, including Alden to the south, and settled on Hartland, to the east. “It was a perfect fit—same size, same number of connections.” Guggisberg and Flatness had often worked together, helping one another’s cities with everything from street sweeping to putting up holiday lights.

Rather than build a new treatment plant itself, Freeborn participated in building a new treatment plant in Hartland, splitting the cost of the plant, which connected to both cities’ distribution systems. Hartland also added two new wells, which are arsenic-free, solving Freeborn’s problems.

The Hartland treatment plant has better aeration and detention to solve the city’s radium issues. As part of the project, Hartland replaced meters and mains and built a 75,000-gallon water tower.

“It was more cost-effective to hook up with Hartland,” explained Pichelmann. “The upside was that the incremental cost to increase the capacity wasn’t much—it was just making a 10-foot diameter gravity filter rather than an 8-to-9 foot diameter filter. The chemical feed didn’t change.”

The new Hartland plant is in front of the city’s water tower and next to the two new wells.

The plant has a packaged filtration unit that combines aeration, detention, and filtration. At the top is aeration, which strips the carbon dioxide and sulfide and oxidizes the iron. The chemical feed during detention includes potassium permanganate, a polymer, and chlorine as needed. The detention time of 30 minutes allows for proper reactions. A four-cell gravity filter at the bottom has 18 inches of greensand on top of 12 inches of anthracite.

Fluoride and chlorine gas provide dental protection and disinfection, respectively. The plant has a capacity of 150 gallons per minute. The economies of scale from two cities using one plant make for lower user costs, and the cities share the operation and maintenance costs proportionally.

Freeborn paid for the interconnection, 30,000 feet of six-inch PVC, as well as 20,000 feet of water mains in town. In addition, Freeborn replaced its meters. The pipeline from Hartland follows Freeborn County Hwy. 33 to the west and then south on Cty. 10 to Freeborn. “It follows the blacktop,” said Flatness, noting that using the main roads avoided the permitting problems they would have encountered had they taken a direct route, which would have involved going through land that had tiles and wind towers.

One of the reasons for placing the new plant in Hartland is because its elevation is about 18 to 20 feet higher than Freeborn, allowing gravity to aid the distribution. The plant has a booster pump, in case it is needed.

The preliminary engineering report for the project was completed in early 2012. The treatment plant was finished in 2013 and the interconnection in 2016.

The cities paid for the project with grants and loans from the Minnesota Drinking Water Revolving Loan Fund, the Public Facilities Authority, and the U. S. Department of Agriculture Rural Development. The total cost was $6,832,400.

The previous Hartland plant is two blocks north of the new one.

Freeborn is now in compliance with the arsenic MCL, and Hartland has alleviated its concerns with radium. In addition, the aesthetic quality of the water has improved as the new plant is effective in reducing iron and manganese. “The people are happy,” said Flatness. “They can get a glass of water with nothing floating in it.”

A joint water board from the two cities runs the system. One city has five members and the other four, with the cities switching that number around every two years.’

“It can be difficult for two communities to create a shared water supply,” said Karla Peterson of MDH, “but it’s encouraging to see when there is a success story.”

Guggisberg echoed Peterson’s sentiments and credited Bolton & Menk as well as MDH district engineer Paul Halvorson. “It was a lengthy process, but it was well worth it,”

“Everybody pitched in to get this job done. It’s basic, it’s simple, it works.”

Go to top

MDH Issues New Water Treatment Fact Sheet: New Server Means New Links for MDH Pages—Update Your Bookmarks

In response to numerous queries from cities and citizens, the Minnesota Department of Health has updated its fact sheet on home water-treatment units:

The fact sheet is part of a more extensive page on home water treatment, which includes other information, such as how to guard against sales scams of water-treatment equipment:

Home Water Treatment Resource Page

Please note that these pages, and others, have new links as MDH has moved its web files to a new server. Be sure to update your bookmarks. The main MDH drinking water page is at:

Go to top

Metro School Draws Big Crowd

Dan DeMuth was the keynote speaker at the Metro District Water Operators School in April with The Power of Focus. A professional golf instructor, DeMuth had participants perform putting exercises and applied the lessons learned on the golf course to life.

Kelsey Griffin, reaching for a dead mouse to feed a hungry eagle, was the breakfast speaker, also bringing a great horned owl, kestral, and red-tailed hawk from The Raptor Center.

One of the hands-on sessions for the operators was a trip to Keys Well Drilling in St. Paul.

The Metro School had a Hydrant Hysteria demonstration.

Go to top

Resilience Planning and Adaptation Training for the Water Utility Sector

On Thursday, July 18, the Minnesota Rural Water Association, Minnesota Department of Health, Minnesota Pollution Control Agency and U.S. Environmental Protection Agency are hosting a free training for drinking water, stormwater and wastewater utilities on resilience planning and adapting to current and future extreme weather threats.

The training will be held in St. Cloud and will introduce the U. S. Environmental Protection Agency's Creating Resilient Water Utilities resources and tools.

There is no fee for the training, and participants will receive 6 contact hours.

Go to top

Minnesota Rural Water Association Lead Service Line Survey

In early April, Minnesota Rural Water Association sent all municipal water systems in Minnesota an electronic survey. The survey asked questions about lead service lines, lead service line funding options, and water rates. This survey was one of the first steps in helping Minnesota create a funding mechanism for lead service line replacement on private property. It will also help the Minnesota Department of Health determine what kind of resources are needed to develop a lead service line inventory across the state in advance of the next round of the U. S. Environmental Protection Agency Drinking Water Needs Survey.

Go to top

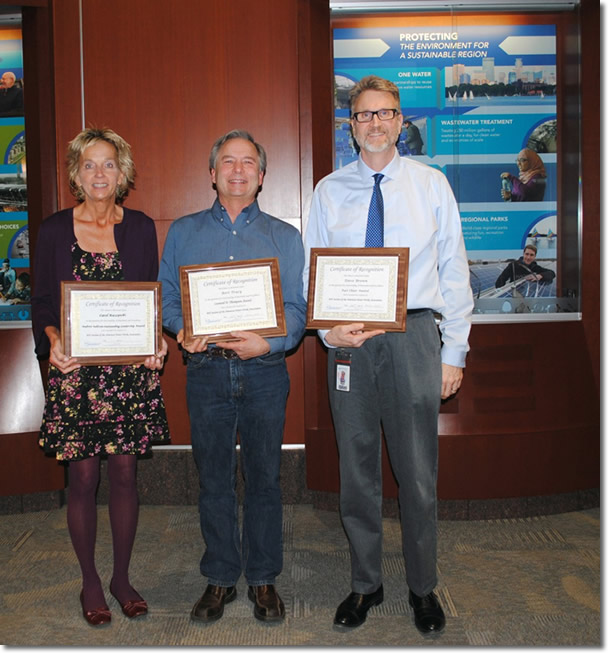

Metropolitan Council Honors Employees for Drinking Water Awards

The Metropolitan Council recently honored three employees—Carol Kaszynski, Bert Tracy, and Dave Brown—for awards they received from the Minnesota Section of American Water Works Association (AWWA) at the section’s annual conference in Duluth last fall. Kaszynski received the Andrew Sullivan Outstanding Leadership Award, Tracy the Leonard N. Thompson Award, and Brown the Past Chair Award.

Go to top

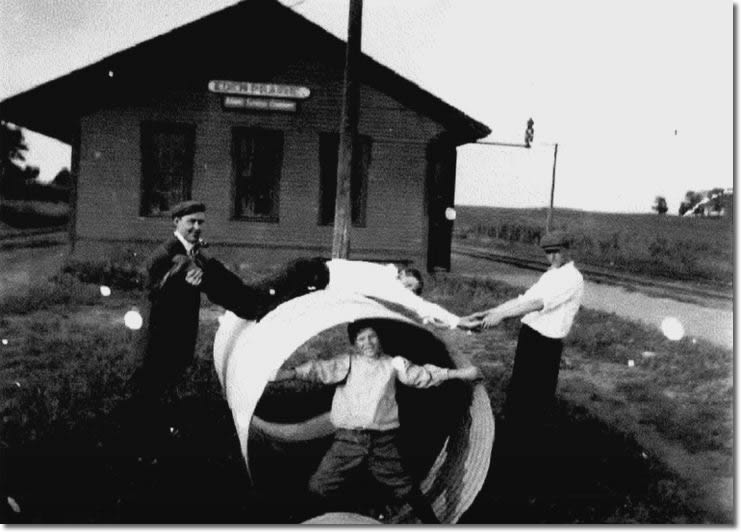

Eden Prairie Reservoir and Pumphouse to Replicate and Recognize History

The Washburn Depot in Eden Prairie, looking east toward Minneapolis.

Eden Prairie grew little over its first 100 years and then boomed over the next half-century, transforming from an outlying agricultural village to a high-tech suburb of more than 60,000 people. Projections call for another 25 percent bump in population over the next 20 years, and the city is ready for it.

Rick Wahlen, Eden Prairie’s manager of utility operations, has been staying ahead of the growth curve to be able to serve the increase in residents as well as the surge in businesses and commercial activity. The past four years have included working with AE2S, Inc. to plan a four-million-gallon ground-storage reservoir and a new pumphouse.

The site selected is between U. S. Hwy. 212 and the Minnesota River Bluffs Regional Trail, which had once been the tracks for the Minneapolis & St. Louis Railroad. To note the historical significance of the area, the pump station design will represent the Washburn Depot, Eden Prairie’s first railroad station, complete with a railroad spur to represent the tracks.

“We’re not attempting to re-create but to represent the original train station,” said Wahlen. The design calls for a long and narrow footprint—similar to the original depot—with a loading platform, which serves as the roof to the pump station.

“It’s a challenge to get a long skinny building to contain a municipal pump station of the size needed. The pump station is actually beneath the structure and is about nine feet wider than the building,” Wahlen explained, adding that they used specific design details from the original building, including wall panels, curved soffits, and flared window trim as well as a decorative fence outside the structure. The new reservoir will be outside the pumphouse building. As an access point to the regional trail, the site will contain signs to explain the area’s history, as well as a pet watering station, park benches, and likely a bike repair station.

Construction on the pump station and reservoir will begin in May 2019 and is scheduled for completion in August 2020.

Artist renderings of the new pumphouse station, with the design of the historic train depot.

Go to top

MDH Guidance to Operator Exposure to Radon at Water Treatment Plants

Radon is a naturally-occurring gas that has no color, odor, or taste and comes from the breakdown of radium-226. Radon may be released from areas with radium accumulation, soil gases, sludge, or water. It can travel easily through cracks in concrete or poorly sealed doors and disperses quickly into the atmosphere. Radon is commonly found in the basements of many homes in Minnesota.

Radon may also be found in water treatment plants that remove radium, and, as a result, water operators may be exposed to elevated concentrations of airborne radon within the treatment plant. The long-term health risk of breathing radon is lung cancer.

Check Existing Conditions

Water treatment plants should be tested for airborne radon, particularly if the treatment plant meets at least one of the following conditions:

• Open detention tanks, filters, backwash basins, or clearwells within the treatment plant

• Backwash waste discharged within the treatment plant (sump)

• Accumulation of radium on filter media or sludge, which produces radon as a daughter product

Measure Risk

Radon detectors (long-term alpha track detectors) are available free of charge from the Minnesota Department of Health for testing at treatment plants. Two radon detectors should be left in place for at least three months during testing. These detectors should be placed near each other, at a normal breathing level, away from walls, and in an area where the water operator spends most of his or her time, such as an office or work area. If the source or treatment plant design changes in the future, the water system may want to retest for radon.

If the radon result is less than 4 picocuries per liter (pCi/L), the treatment plant meets the U. S. Environmental Protection Agency’s recommended standard for radon in homes, and the amount of occupational exposure may be limited. If the result is greater than 4 pCi/L, the plant supervisor may contact MDH for information on additional testing.

Reduce Exposure

A significant amount of exposure may occur both during the backwash cycle and throughout the day. Listed below are several recommendations to help to reduce water operator exposure to radon in treatment plants.

• Provide adequate ventilation continuously or when the operator is in the treatment plant.

• Use an exhaust fan located directly above the backwash sump during the backwash cycle.

• Keep the backwash sump in a well-ventilated room separate from the rest of the plant.

• Minimize radium accumulation on filter media by replacing or cleaning filter media.

• Limit time spent in the plant during or shortly after the backwash cycle, or use automatic backwash controls.

A radon test kit costs between $5 and $30, depending on the type of kit. Some test kits may also require an analysis fee paid after mailing the kit to the lab.

- Air Chek, Inc. a manufacturer of short term radon test kits. Minnesota residents receive a discount.

- Radonova a manufacturer of long term radon gas test kits. Minnesota residents receive a discount.

- The local contacts are usually affiliated with local city or county health departments. They distribute radon information and/or radon test kits to local resident, see list of Local Radon Contacts.

Contact MDH compliance engineer Anna Schliep, anna.schliep@state.mn.us, 651-201-4667 to obtain information about occupational exposure and testing for radon.

Go to top

Promote Water Careers in Consumer Confidence Reports

By Carol Kaszynski

Minnesota Section of American Water Works Association

Science, Technology, Engineering, Math (STEM) Committee Chair

Some cities, including Minneapolis, are promoting careers in water in their Consumer Confidence Report. You can, too. Here’s a sample of what you can add:

A Career in the Water Industry Is Waiting for YOU!

St. Cloud Technical and Community College and Vermilion Technical College provide you with the skills you need to land a great job in the Water Environment Technologies rapidly growing industry. There are many benefits to these programs:

► Hands-on learning

► 12 month program

► Metro, St. Cloud, and Ely locations

► 100% placement rate

Call St. Cloud Technical and Community College at 1-320-308-5952 for more information on this career program or e-mail Mark Weikert, Instructor: marcus.weikert@sctcc.edu, St. Cloud Technical and Community College, 320-308-5952, or Gregg Kropp, Instructor: gregg.kropp@sctcc.edu, Vermillion College, 800-657-3608.

Go to top

Complying with America's Water Infrastructure Act

On October 23, 2018, America’s Water Infrastructure Act (AWIA) was signed into law. The law requires community drinking water systems serving more than 3,300 people to complete risk and resiliency assessments (RRAs) and emergency response plans (ERPs). Detailed information that explains submittal procedures and identifies tools and resources to assist with completing RRAs and ERPs will be provided by August 1, 2019. The U. S. Environmental Protection Agency (EPA) requests that systems wait until after August 1, 2019 or the deadlines listed here to submit risk assessments and ERP certifications.

Certification Deadlines

| Population Served | Risk Assessment | Emergency Response Plan |

|---|---|---|

| 100,000 or more | March 31, 2020 | September 30, 2020 |

| 50,000 to 99,999 | December 31, 2020 | June 30, 2020 |

| 3,301 to 49,999 | June 30, 2021 | December 30, 2021 |

Risk and Resilience Assessment Requirements

Each community water system serving a population of greater than 3,300 persons shall assess the risks to, and resilience of, its system. Assessments include:

- the risk to the system from malevolent acts and natural hazards;

- the resilience of the pipes and constructed conveyances, physical barriers, source water, water collection and intake, pretreatment, treatment, storage and distribution facilities, electronic, computer, or other automated systems (including the security of such systems) that are used by the system;

- the monitoring practices of the system;

- the financial infrastructure of the system;

- the use, storage, or handling of various chemicals by the system; and

- the operation and maintenance of the system.

Emergency Response Plan Requirements

No later than six months after certifying completion of its risk and resilience assessment, each system must prepare or revise an emergency response plan that incorporates the findings of the assessment. The plan includes:

- strategies and resources to improve the resilience of the system, including the physical security and cybersecurity of the system;

- plans and procedures that can be implemented and identification of equipment that can be used, in the event of a malevolent act or natural hazard that threatens the ability of the community water system to deliver safe drinking water;

- actions, procedures, and equipment that can obviate or significantly lessen the impact of a malevolent act or natural hazard on the public health and the safety and supply of drinking water provided to communities and individuals, including the development of alternative source water options, relocation of water intakes, and construction of flood protection barriers; and

- strategies that can be used to aid in the detection of malevolent acts or natural hazards that threaten the security or resilience of the system.

Certification Process

Detailed information on submittal procedures will be provided by August 2019. Systems will not submit their plans but will submit a certification instead. Three options will be provided for submitting risk assessment and emergency response plan certification: mail, email or secure portal.

Five-year Review, Revision, and Certification Requirements

Each community water system serving more than 3,300 people must review its risk and resilience assessment at least once every five years to determine if it should be revised. Upon completion of such a review, the system must submit to the EPA a certification that it has reviewed its assessment and revised it, if applicable.

Standards and Tools

While methods and tools can facilitate the development of sound risk assessments, no tool or standard guarantees compliance with the AWIA. Community water systems must review their completed RRAs and ERPs and ensure that they comply with all AWAI requirements.

Available by June 1—New AWAI requirements in the Federal Register Notice, Compliance Fact Sheet, and Technical Assistance Primer and Information-on-Certification Procedures.

Available August 1—Baseline Threat Information for completing Risk and Resilience Assessments, VSAT 2.0 and ERP Tool, and AWAI Webinars and other training opportunities.

Latest updates and information about the AWIA can be found at theEPA website:

America's Water Infrastructure Act of 2018: Risk Assessments and Emergency Response Plans

Go to top

Past Waterlines Archived at wateroperator.org

The Minnesota Department of Health is archiving past issues of the Waterline for only the previous three years. However, wateroperator.org is hosting past issues back to 1997.

To access these, go to Search for Documents. Select the following filter criteria: HOST – Minnesota Department of Health; TYPE – Newsletters/Magazines; STATE – Minnesota. Click the “Retrieve Documents” button.

Go to top

Words to Live By

“Every researcher knows that the thing you’re looking for leads you to the thing you weren’t looking for and is much better than the thing you were looking for.”

—William Grimes, New York Times obituary writer, in the documentary Obit

“Every strike out brings me closer to the next home run.”

—Babe Ruth

Go to top

Reminder to All Water Operators

When submitting water samples for analyses, remember to do the following:

- Take coliform samples on the distribution system, not at the wells or entry points.

- Write the Date Collected, Time Collected, and Collector’s Name on the lab form.

- Attach the label to each bottle (do not attach labels to the lab form).

- Include laboratory request forms with submitted samples.

- Do not use a rollerball or gel pen (the ink may run).

- Consult your monitoring plan(s) prior to collecting required compliance samples.

Notify your Minnesota Department of Health district engineer of any changes to your systems.

If you have questions, call the Minnesota Department of Health contact on the back of all sample instruction forms.

Calendar

Operator training sponsored by the Minnesota Department of Health and the Minnesota AWWA will be held in several locations this spring.

Register for schools and pay on-line:

Go to top