Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Waterline: Winter 2017 - 2018

Editor:

Stew Thornley

Subscribe to The Waterline newsletter. An e-mail notice is sent out each quarter when a new edition is posted to the web site.

On this page:

- Ortonville Gets New Water Plant

- Minnesota Department of Health Profile: Anna Arkin

- Lewis & Clark Shooting for the Moon

- Good News and Bad News on the Bottled Water Ban in National Parks

- Plate Settlers Clean Up Ortonville Water

- MDH Adopts GRAPS

- Ultraviolet Technology Project First in State to Address Dioxane Contamination

- Lessons Learned in Blaine

- Sports and Water

- Drinking Water Institute in Lakeville

- Lake Elmo Sweeps Doubleheader in State Fair Taste Test

- Award Recipients at Minnesota AWWA Conference

- Waterline Reader Survey: Please Help Us to Help You Get More out of the Waterline

- Reminder to All Water Operators

- Calendar

Ortonville Gets New Water Plant

Separated from South Dakota by Big Stone Lake, Ortonville is a small and thriving community in western Minnesota. At the end of the last Ice Age, the lake was at the southernmost extent of Lake Agassiz, which reached all the way to what is now Winnipeg. Fed by the melting glaciers that carved Minnesota’s topography, Lake Agassiz drained into the great River Warren, the predecessor to the Minnesota River, which meanders from Big Stone Lake through southern Minnesota to its confluence with the Mississippi River at Fort Snelling in the Twin Cities. Though its history includes being part of the largest body of water in North America, Ortonville uses wells to supply its 1,900 residents as well as Big Stone City, South Dakota. Its history of water supply is diverse and includes a recent upgrade of its water treatment plant with plate settlers installed as an innovative and cost-effective solution to improving the quality of the water.Full story below.

Go to top

Minnesota Department of Health Profile: Anna Arkin

Anna Arkin has joined the Drinking Water Protection Section at the Minnesota Department of Health as a planner and health communicator. A native of Arlington, Virginia, Anna came to the Midwest for college (Washington University in St. Louis) and recently graduated with a master’s degree in public health from the University of Minnesota. She worked for the Minnesota Technical Assistance Program, providing technical assistance to Minnesota businesses on waste reduction and pollution prevention, and interned at the governor’s office, working on health policy. Anna has a husband, David, and a dachshund/Jack Russell terrier mix, Nellie. Anna has been to 40 states and is working on the final 10.

Anna

Nellie

Go to top

Lewis & Clark Shooting for the Moon

Construction on the Rock County pump station, part of the Lewis & Clark Regional Water System

The Lewis & Clark Regional Water System (LCRWS) marked its five-year anniversary of delivering water in July. The start of operations was the culmination of many years of planning and construction as a way of serving water-challenged areas in South Dakota, Iowa, and Minnesota. The Lewis & Clark project takes water from a series of wells that tap into an aquifer adjacent to the Missouri River near Vermillion, South Dakota. The water is delivered to communities as far away as 125 miles.

LCRWS executive director Troy Larson says that the project has delivered 21.3 billion gallons of water since its start up and that it set a new daily record on July 17 with 23.4 million gallons.

The water made its way to Minnesota in May 2015, reaching Rock County Rural Water District outside Luverne. Larson notes that Rock County is the only county in the state without a naturally occurring lake, which “reiterates the importance of getting water to the county and area.”

LCRWS water in Minnesota has since reached Magnolia and Adrian, a connection point to Lincoln-Pipestone Rural Water System, which supplies water to 38 communities in 10 counties. Worthington is expected to be connected by the end of 2018.

“Looking ahead, it sure would be great if we could get the remaining members connected before we hit our 10-year anniversary,” Larson said. “That’ll be our version of a ‘moon shot.’”

Go to top

Good News and Bad News on the Bottled Water Ban in National Parks

The Winter 2015-2016 Waterline contained an article on the National Park Service taking a stand by discouraging the sale of bottled water at its parks despite pressure on Congress from the International Bottled Water Association to cut off federal money the Park Service is using to install bottle-filling stations as an alternative to bottled water.

The follow-up to this story has good news and bad news. First, the good. The Washington Post reported September 26, 2017 that a National Park Service’s ban on the sales of bottled water resulted in annual savings of up to two million water bottles, which prevented 112,000 pounds of plastic from being sold and discarded each year “along with up to 140 metric tons of carbon dioxide emissions,” according to the Post.

However (and here’s the bad stuff), the current administration rescinded the ban in August 2017, the result of lobbying from the International Bottled Water Association.

The Park Service is still encouraging visitors to avoid bottled water by selling reusable bottles and installing bottle-filling stations in its parks. Meanwhile, Representative Mike Quigley of Illinois has introduced legislation to reinstate the ban on selling bottled water at National Park Service sites.

Go to top

Plate Settlers Clean Up Ortonville Water

Stationed on Big Stone Lake in Ortonville, a 1933 building originally housed pumps to get water from a pair of wells to residents in higher parts of the city.

High levels of iron and manganese in the groundwater prompted the city to add filters and transform the facility into Ortonville’s first water treatment plant in the 1960s.

In 1997 Ortonville teamed with Big Stone City, across the lake in South Dakota, to open the Big Stone Area Treatment Plant, one that serves both cities. Two wells in sediment in the river plain pump water to the treatment plant, which is farther inland than the previous one and on a hill about 400 feet higher than the wells.

The new plant included a flocculation basin, unlike the direct filtration in the original plant, to allow detention time for contaminants, reducing the amount of iron and manganese that reaches the filters. The plan for the 1997 facility was to add lime softening, but the process was dropped because of the cost. The hardness of the water in the ground is approximately 1,100 parts per million (ppm) as calcium carbonate. Most residents of Ortonville have water softeners in their homes.

|

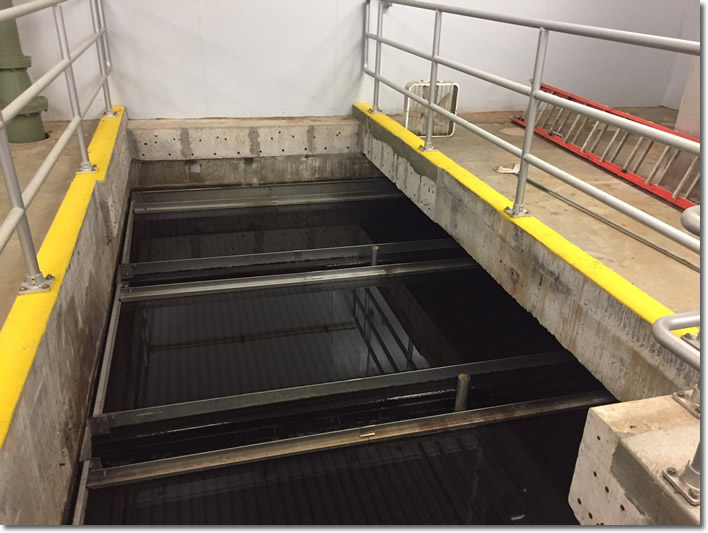

| Plate settlers (above) were added to the treatment process in Ortonville to reduce the load on the filters (below). |

|

The raw water also has 5 ppm of iron and .5 ppm of manganese, both high enough to cause noticeable aesthetic effects in the water. The new plant did its job in lowering the iron and manganese levels while producing about 1,000 gallons per minute. High service pumps delivered water across the state line to Big Stone City, which has a smaller population (about 450) but also provides water to an ethanol plant.

However, the filter runs at the plant were short, often only five hours. John Thom of SEH, Inc. of Vadnais Heights, Minnesota, says the raw water is high in organic matter, causing problems with the oxidation of the iron in pre-treatment. The result was short circuiting in the flocculator, resulting in too much load on the filters.

SEH, Inc. worked with Ortonville on a pilot study to explore remedies and chose plate settlers as the solution. The city considered but rejected the costly option of adding to the building. Instead, it moved a stairway, put in flocculation basins, and reused the old detention tanks as plate settlers.

|

| Above: the original plant, which was a booster station for wells by the lake when it opened in 1933. Below: the 1997 plant, which retained its original size despite the addition of plate settlers. The beams and plate settlers were hoisted to the roof and brought in through a second-story door. |

|

Plate settlers have long been used in wastewater treatment. Their more-recent use in water plants has been for backwash reclaim. “Here, they are used for the iron and manganese removal,” said Thom, who explained that incoming water is aerated and then has chlorine, permanganate, and a polymer added as it enters the flocculation basin. “Then it flows in under the plate settler, and the particles rise. The plates are slanted. Particles travel up in a straight line, settle to a plate, and fall back into the sludge collector. Clear water comes off the top.”

Rather than 4 to 5 ppm of iron reaching the filters, now only about .5 ppm gets there, a 90 percent reduction in filter loading. Manganese dropped from .5 ppm to .1 ppm because of the plate settlers. “Instead of short filter runs, they are now pushing 100 hours although they will backwash at least once a week,” said Thom. “Before, they couldn’t recycle the water. It was all going to ponds. Now only the sludge goes out.”

Recovering the backwash water will result in less water usage, enough that the savings in water will cover the project cost, approximately $750,000, in six or seven years. Said Thom, “We got a big impact with a small outlay of dollars.”

|

| Above: Ortonville’s two wells, near Big Stone Lake. Below: Ortonville operator Sam Berger with John Thom of SEH, Inc. |

|

Go to top

MDH Adopts GRAPS

Supported by the Clean Water Fund, the Minnesota Department of Health is developing a Groundwater Restoration and Protection Strategies (GRAPS) process.

The purpose of GRAPS is to translate data from ongoing groundwater and drinking-water programs to the watershed scale and to work with other agencies to develop watershed-scale groundwater and drinking-water management strategies to integrate into local water management plans.

MDH released its first report, on the North Fork River Watershed, in June 2017 and is working on GRAPS reports for the Cannon River and Missouri River Basin watershed.

Groundwater Restoration and Protection Strategies

Go to top

Ultraviolet Technology Project First in State to Address Dioxane Contamination

By Greg Johnson

WSB & Associates, Inc.

Officials from the U. S. Army participated in the ribbon cutting for the addition to St. Anthony Village water treatment plant August 9, making it one of the the first in the state to use ultraviolet (UV) light technology and hydrogen peroxide together to treat drinking water. Chemicals used at the former Twin Cities Army Ammunition Plant in Arden Hills contaminated soil and groundwater. St. Anthony’s plant already removed trichloroethylene and now will remove 1,4-dioxane as well.

The city of St. Anthony Village recently completed an addition to its water treatment plant that uses ultraviolet (UV) light technology to remove 1,4-dioxane, a contaminant of emerging concern, in the city’s municipal wells. The plant is one of the first in Minnesota to use UV technology and hydrogen peroxide together in a potable water system, although it is being used successfully in dozens of other treatment systems across the country to remove the contaminant from more than 250 million gallons of drinking water each day.

Patented by the Dow Chemical Company, 1,4-dioxane was widely used as a stabilizing additive for trichloroethylene (TCE), a chlorinated solvent used as a degreaser. The use of these chemicals for many years at the Twin Cities Army Ammunition Plant in Arden Hills was found in 1987 to have contaminated soil, sediments, surface water, and groundwater. St. Anthony Village’s water treatment plant already removes TCE from the municipal water system.

The health risk limit of 1 part per billion (ppb) established by the Minnesota Department of Health (MDH) for 1,4-dioxane was exceeded for the first time in one of the city’s three wells, Well No. 4, in June 2015. It has not been detected in the distribution system. The well was immediately shut down; however, ongoing testing indicated that levels in the other two wells were slowly rising as the dioxane plume moved southwest.

WSB & Associates of St. Paul was retained in July 2015 to evaluate the options available to the city to address the problem, based on objectives set by the city council. Five options included blending water from the city wells to dilute 1,4-dioxane to below Minnesota Department of Health guidance limits; extending existing wells or constructing new wells into the deeper Mount-Simon Hinckley aquifer; purchasing water from Minneapolis; purchasing water from St. Paul Regional Water Services; and implementing treatment.

WSB’s Water/Wastewater Group studied Environmental Protection Agency pilot plant studies employing treatment technologies for 1,4-dioxane and concluded that modifying the plant to treat the contaminant with ultraviolet light and hydrogen peroxide (H2O2) was the most cost-effective solution for the city. When added to water in a vendor-supplied UV reactor, the hydrogen peroxide absorbs UV light, producing hydroxyl radicals that break down 1,4-dioxane into nontoxic compounds consisting of carbon dioxide, water, and residual chloride. This advanced oxidation process is also effective in treating other volatile organic compounds (VOCs) that may be present, including TCE.

In the presence of MDH officials, WSB engineers and representatives of Trojan Technologies Inc. conducted a pilot treatment in August 2015 using a sample tap downstream of the plant’s greensand filters, which treat turbidity and remove iron and manganese. The water was spiked with dioxane to test whether the treatment would remove more than 99.9 percent of the contaminant and piped into Trojan’s UVPhox unit. Following UV oxidation, the water was routed back to the plant’s existing granular activated carbon filters (GAC) to quench any excess hydrogen peroxide and remove TCE and any remaining VOCs.

The benefits of pursuing UV light technology were considerable. The treatment physically destroys and removes dioxane from the environment and does not create other contaminants that require disposal as hazardous materials; in other words, the treatment cleans the aquifer, reducing risk to other users of the aquifer located downstream of St. Anthony Village. It can not only be used in conjunction with the city’s other treatment processes, but enhances those processes to remove TCE and other contaminants. Use of the city’s three existing wells can continue, including Well No. 4; the pilot study demonstrated that the treatment system can successfully treat increases in dioxane levels. The city also remains in control of its own municipal water supply system.

Design began in April 2016. Siting a new building within the small footprint of St. Anthony Village’s existing treatment plant site necessitated the removal of a pumphouse and installation of new booster pumps inside the new plant addition. Its ideal location adjacent to the GAC filter building also required that a specially designed foundation system be located beneath the filter building. Plans called for three UVPhox units to accommodate a design flow of 3,000 gallons per minute (gpm) and an average flow of 1,250 gpm, a chemical storage room with two 3,000-gallon bulk storage tanks, a 60-gallon day tank, and a hydrogen peroxide feed system. Flow from the greensand filters is metered and split between treatment units in response to water demands using automated control valves via an expanded plant automation control system. Water is then routed back to the GAC filters to complete treatment.

Construction began late that summer; challenges included keeping the existing treatment processes in service and minimizing disruption to the plant. Complete tie-in was accomplished during the off-season over two separate days. At a cost of $6.7 million, well below the engineer’s estimate of $7.2 million, construction was finished in July 2017, just two years after Well No. 4 was removed from service.

Go to top

Lessons Learned in Blaine

Part I

At 8:25 a.m. on Sunday, January 8, George Linngren got a call every utilities superintendent dreads. The on-call duty officer for the city of Blaine, a northern Twin Cities suburb, told Linngren that residents were calling because they weren’t getting water. The outage was not localized; the calls were coming from across the city.

Linngren headed for his office and found that all of the city’s towers were empty. (Blaine has four towers, and one was out of service.) Two pumps at one of the treatment plants had failed the night before. The SCADA system had worked as it should—indicating the empty towers—but the WIN 911 dialer had not called out to indicate the alarms.

Crews went to work, turning on other wells in addition to starting up auxiliary wells that had been taken out of service for the winter. The adjacent suburbs of Spring Lake Park and Coon Rapids opened their emergency bypasses, and water was flowing to Blaine again.

Linngren contacted the state duty officer and talked to David Weum, the engineer who was from the Minnesota Department of Health. Weum advised Linngren to issue a boil water advisory in case bacteria had entered the system during the time the pressure had been low. Social media was a valuable tool for getting the word out, and local television stations put a crawl at the bottom of the screen advising Blaine residents to boil their water before using it for drinking or cooking.

By 11:00 a.m. messages started appearing on the city’s Facebook site from residents reporting that their water was returning, although the boil water advisory would have to remain until the city could get sample results back.

As part of activating the Blaine’s Emergency Operations Center, Linngren got calls from a joint terrorism task force of the FBI and Homeland Security. The task force wanted to make sure the situation was caused by a mechanical failure and not from anyone with malicious intent. The police department collected some computers and downloaded the hard drives on others to see if the system had been hacked. (It hadn’t.)

Linngren also learned a lesson about having emergency phone numbers for its laboratories. Unable to connect with the utility’s regular labs, Linngren was able to reach the laboratory for St. Paul Regional Water Services. The city collected samples Sunday afternoon and took them to St. Paul.

Schools in Blaine were closed on Monday, and later in the day the processing of the water samples was complete, with no contamination detected.

Life with water was able to return to normal for Blaine residents, although the utility remained busy, assessing what happened and taking steps to prevent a repeat of the problem.

Following emergency procedures already in place, Blaine was able to get through the crisis in a timely manner.

Part II

Five weeks later Linngren received one of those calls that produces a “You gotta be [&%$#*@!] me” reaction. At 5 p.m. on Sunday, February 12, his 52nd birthday, Linngren was notified that there was no pressure in the system again. A battery backup failed, and the alarms that were generated didn’t make it to the automatic dialer.

Linngren and the city went through the same routine again, although this time the process was a bit smoother, in part because of lessons learned from the first time, such as having backup numbers for the labs. With no way to be certain if the pressure had dipped below 20 pounds per square inch, and, if so, for how long, the city issued another boil water notice and worked with MDH to sample the water.

They got the samples to the lab by 11:00 that night, and the samples came back clean within 24 hours but not before Blaine schools had to close again for a day.

More lessons have been learned, and Linngren said their communication through social media and other means produced “a lot of understanding from the public.”

Blaine continues to assess what went wrong and what the city will do to prevent such problems again. As Linngren summarized, “The first time it’s painful. The second time it’s real painful.”

Go to top

Sports and Water

Baseball

The newly refurbished Valley View water tower in Bloomington was a backdrop for the Minnesota Class A amateur baseball tournament in August. The rehabilitation of the 50-year-old tower included removal and replacement of coatings, structural repairs, and safety upgrades. The tower is surrounded by a security fence behind the left-field fence. A long home run by the St. Paul Capitals’ Ryan Abrahamson—which broke a scoreless tie with the Minneapolis Angels in the 12th inning on Sunday, August 14—landed next to the tower. The ball was retrieved by a city crew the next day. The Minnesota Class C tournament opened in Green Isle the following weekend beneath that city’s water tower. (At the bottom is a photo of Green Isle’s long-gone wooden tower, replaced in 2001 by the current tower.)

The newly refurbished Valley View water tower in Bloomington was a backdrop for the Minnesota Class A amateur baseball tournament in August. The rehabilitation of the 50-year-old tower included removal and replacement of coatings, structural repairs, and safety upgrades. The tower is surrounded by a security fence behind the left-field fence. A long home run by the St. Paul Capitals’ Ryan Abrahamson—which broke a scoreless tie with the Minneapolis Angels in the 12th inning on Sunday, August 14—landed next to the tower. The ball was retrieved by a city crew the next day. The Minnesota Class C tournament opened in Green Isle the following weekend beneath that city’s water tower. (At the bottom is a photo of Green Isle’s long-gone wooden tower, replaced in 2001 by the current tower.)

Hockey

The Minnesota Wild is expanding the sources of water for its ice at Xcel Energy Center. Since the arena opened in 2000, the team has used St. Paul water to make the ice its rink. “It’s really good for making ice,” said Travis Larson, the manager of ice operations for the arena.

This season, however, the team is allowing Minnesota fans to bring water to be mixed in as part of their ice surface. More than 2,400 fans of all ages brought water for the Wild’s “This Is Our Ice” launch event on Saturday, September 16. The Wild had its Zamboni in the lobby of the arena, and fans deposited three ounces of their hometown water—from taps, wells, ponds, lakes, and streams—to fill the ice-resurfacing machine. The water came from 299 cities, mostly from Minnesota but also from such distant sites as Maine, New York, California, North Carolina, and Hawaii.

The water was filtered to remove solids, disinfected, mixed with St. Paul water in the 190-gallon Zamboni tank, and used to resurface the ice the next day.

Larson said they make ice for the upcoming season with hoses and a flood tank around Labor Day each year. A one-inch sheet of ice takes about 10,000 gallons of water. The ice remains all season and is covered when other events are held on top of it. The ice is frequently resurfaced, especially during games, with the Zamboni shaving off and putting on a new layer.

The campaign will continue during the 2017-2018 season. Fans can deposit their water before each home game. After filtering and disinfecting, the water will be used in the resurfacing after the second period.

“It’s been an interesting process, and we’ll make it work” said Larson. “Fan support for this campaign has been tremendous.”

Go to top

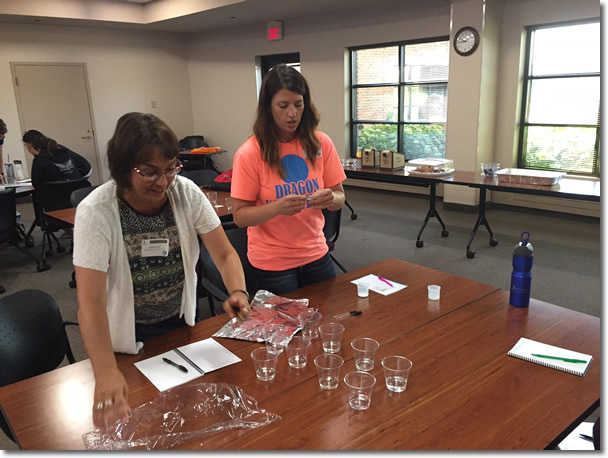

Drinking Water Institute in Lakeville

The annual Drinking Water Institute for Educators drew 20 teachers for a three-day workshop at the Lakeville water treatment plant. Water superintendents and representatives Jodi Wallin of St. Paul, Paul Coone of Roseville, Dana Bjork of Lakeville, Mark Peine of Hastings, and Todd Osweiler of Rochester attended on one of the days to meet with teachers from their cities. The 2018 Drinking Water Institute will be August 6-8 in Rochester.

Drinking Water Institute Information

Go to top

Lake Elmo Sweeps Doubleheader in State Fair Taste Test

Members of the Minnesota Section of American Water Works Association (AWWA) were on WCCO Radio following the Great Minnesota Tap Water Taste Test, which was held on the Sustainability Stage in the Eco Experience building at the State Fair on Monday, August 28, a competition that Minnesota AWWA has held since 2012. This year, Lake Elmo won the contest. St. Louis Park, Plymouth, and North St. Paul were the other finalists. The Lake Elmo water was brought to WCCO’s State Fair studio and put through another competition as WCCO audience members sampled water from a number of different cities and once again picked Lake Elmo as the best tasting.

Water Bar was a hit at the State Fair. The bar provided tasting of water from cities around the state and the chance for volunteers to talk with visitors about their water.

Another attraction at the fair was the Minnesota Department of Health exhibit on drinking water.

MDH commissioner Ed Ehlinger (in the bow tie) visited the exhibit during the fair.

Go to top

Award Recipients at Minnesota AWWA Conference

The Minnesota Section of American Water Works Association held its annual conference in Duluth in September and honored the following people:

Benjamin G. Mason Award of Excellence – Paul Thom, Core & Main

Operator Meritorious Service Award – Roger Hagman, City of Bemidji

L. N. Thompson Award – Steve Schneider, St. Paul Regional Water Services

George Warren Fuller Award – Pat Shea, St. Cloud Public Utilities

Jon Eaton Excellence in Volunteering Award – Brian LeMon, Barr Engineering

Go to top

Waterline Reader Survey: Please Help Us to Help You Get More out of the Waterline

The Drinking Water Protection Section of the Minnesota Department of Health seeks your input regarding the Waterline publication, as we plan for future publications.

Please help us by completing this survey.

Go to top

Reminder to All Water Operators

When submitting water samples for analyses, remember to do the following:

- Take coliform samples on the distribution system, not at the wells or entry points.

- Write the Date Collected, Time Collected, and Collector’s Name on the lab form.

- Write the Sample Point on lab forms for bacteriological and fluoride samples.

- Attach the label to each bottle (do not attach labels to the lab form).

- Include lab forms with submitted samples.

- Do not use a rollerball or gel pen; the ink may run.

- Consult your monitoring plan(s) prior to collecting required compliance samples.

Notify your Minnesota Department of Health district engineer of any e-mail changes for contact people.

If you have questions, call the Minnesota Department of Health contact on the back of all sample instruction forms.

Calendar

Operator training sponsored by the Minnesota Department of Health and the Minnesota AWWA will be held in several locations this spring.

Register for schools and pay on-line:

Go to top