Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Waterline: Winter 2019-2020

Editor:

Stew Thornley

Subscribe to The Waterline newsletter. An e-mail notice is sent out each quarter when a new edition is posted to the web site.

On this page:

- Innovation in Lafayette and New Ulm

- Service Connection Fee to Increase January 1, 2020

- Metro School to Have Special Day for Superintendents

- Water on Tap at Minnesota State Fair

- Bloomington Water: Rushin Endorsed

- EPA Considers Regulating Perchlorate: Minnesota Systems Unlikely to be Affected

- Good Ol' Minneapolis Tap Water a Hit at Cedar-Riverside Health Fair

- Unregulated Contaminant Monitoring Project

- Southern Minnesota Cities Turn to Innovative Methods: New Ulm and Lafayette

- Drinking Water Institute in Oakdale

- New Brighton Keeps on Pumping

- MDH Issues Guidance to Operator Exposure of Radon at Water Treatment Plants

- Professional Operator Development Course Set for 2020

- New Addresses for Minnesota Department of Health Water Websites

- MDH to Reduce Printed Copies of Waterline

- Reminder to All Water Operators

- Calendar

Innovation in Lafayette and New Ulm

The south-central Minnesota cities of Lafayette (left) and New Ulm (right) are going to relatively new methods of dealing with iron, manganese, and ammonia. They may also be sharing technology as a pilot unit installed in Lafayette to examine biological filtration may be moving to the New Ulm plant.

Go to top

Service Connection Fee to Increase January 1, 2020

The Minnesota Legislature has voted to increase the safe drinking water fee (also known as the service connection fee) to $9.72 cents per year per service connection.

The fee was established in 1992; it directed each municipal water system to collect and forward the funds to the Minnesota Department of Health (MDH) to cover the cost of testing public water systems as well as for inspections, source water protection plans, and technical assistance to the 7,000 public water systems in the state.

Originally $5.21, the fee was increased to $6.36 in 2005. Since that time, inflation alone has raised costs 28 percent while additional challenges have arisen, such as addressing new threats to drinking water, like pharmaceuticals and harmful algal blooms. MDH temporarily made up the difference by using money from the U. S. Environmental Protection Agency Drinking Water Revolving Fund, leaving less money for communities to make infrastructure improvements.

“With the fee increase, we will be able to continue our proactive approach to drinking water protection,” said Sandeep Burman, manager of the MDH Drinking Water Protection Section. “This approach, including sampling and technical assistance, results in 99 percent compliance with the Safe Drinking Water Act year after year.”

Burman noted that MDH services are especially helpful to small, rural water systems, which have more difficulty meeting water standards. Because of smaller customer bases, these systems have fewer resources for testing, investigations, and physical improvements.

“The safe drinking water fee increase,” Burman added, “along with our strong relationships with drinking water operators and partnerships with other organizations, will continue to help us ensure that everyone, everywhere in Minnesota has access to safe and sufficient drinking water.”

The fee increase will go into effect January 1, 2020.

For more information: Service Connection Fee

Go to top

Metro School to Have Special Day for Superintendents

The 2020 Metro District Water Operators School—which will be held at the Earle Brown Heritage Center in Brooklyn Center from Tuesday, March 31 to Thursday, April 2—will feature a special day for water superintendents. All superintendents are invited to attend at the special price of $25 on April 2. The registration will cover the product exposition, lunch, and a one-hour Superintendent Forum led by Joe Dusek of Eden Prairie.

Go to top

Water on Tap at Minnesota State Fair

Water Bar was back at the State Fair, one of the busiest stops for visitors to the Eco Experience building. Next to Water Bar was a new display at the Minnesota Department of Health exhibit, a giant faucet, under which fairgoers could pose with a sign revealing their primary source of water.

Minnesota American Water Works Association (AWWA) held its eighth annual Great Minnesota Tap Water Taste Test with the audience serving as judges, Crookston was voted the best tasting water in Minnesota. Its water—along with the water of the other finalists, Le Sueur, Waite Park, and Belle Plaine—was brought to the WCCO Radio booth, where Paul Douglas and Jordana Green tasted the water. Other cities entering water were Farmington, Chaska, St. Peter, Excelsior, St. Paul, Eagan, Richfield, Fairmont, Carver, Victoria, Randolph, Moorhead, St. Cloud, Detroit Lakes, Perham, Jordan, Burnsville, Blaine, Lino Lakes, Waconia, Bloomington, and Minneapolis.

Go to top

Bloomington Water: Rushin Endorsed

Noted writer and essayist Steve Rushin is from Bloomington and praised his hometown water in his memoir, Sting-Ray Afternoons.

Writing about his dad’s tendency to show off his knowledge on family vacations, Rushin refers to it as “a kind of exhibitionism, designed to remind us he knows things, has favorite bars and restaurants in cities around the world.

"Oftentimes this knowledge will flatter Bloomington. ‘I've traveled everywhere,’ he likes to say, ‘and Bloomington has the best tap water in the world.’ And he’s right. Bloomington’s tap water—from kitchen sink, from backyard hose, from burbling hallway fountains at Nativity—is renowned.”

Go to top

EPA Considers Regulating Perchlorate

Minnesota Systems Unlikely to be Affected

The U. S. Environmental Protection Agency (EPA) is proposing a maximum contaminant level (MCL) and MCL goal (MCLG) for perchlorate of 0.056 parts per million (ppm). Perchlorate is a chemical compound from commercially produced sales. The EPA has been studying perchlorate because of potential contamination to water, which can reduce hormone production in the thyroid gland.

The EPA is proposing requirements for water systems to conduct monitoring and reporting for perchlorate and to provide information about perchlorate to their consumers through public notification and consumer confidence reports. It includes a list of treatment technologies that would enable water systems to comply with the MCL, including affordable compliance technologies for small systems serving 10,000 persons or fewer.

The EPA is also considering and has sought public comments on instead setting the MCL and MCLG at 0.018 ppm or at 0.090 ppm.

Another alternative is to not regulate perchlorate in drinking water based on new information that perchlorate does not occur in public water systems with a frequency and at levels of public-health concern.

The Minnesota Department of Health tested some community water systems in the state under the first Unregulated Contaminant Monitoring Rule in the early 2000s; it found no detections over 0.018 ppm. As a result, the department does not anticipate many, if any, MCL violations among public water systems in the state, even if a standard is adopted.

Go to top

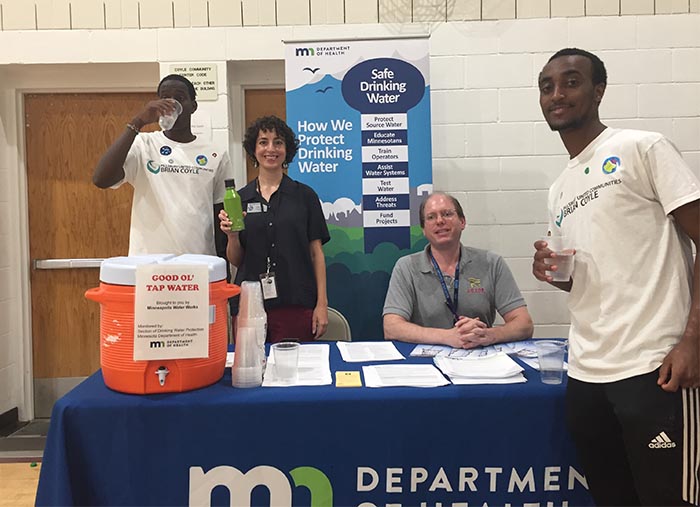

Good Ol' Minneapolis Tap Water a Hit at the Cedar-Riverside Health Fair

Anna Arkin of the Minnesota Department of Health and Chris Rydell of Minneapolis Water Works provided information and the healthiest drink possible August 2 at the Cedar-Riverside Health Fair at the Brian Coyle Center in Minneapolis. The event drew hundreds of residents from the neighborhood, and it was reassuring to learn that attendees—most of whom were from parts of the world where they cannot trust the safety of their drinking water—drank plenty of water from Minneapolis Water Works from a jug that was refilled several times because of the high demand.

Go to top

Unregulated Contaminants Monitoring Project

The Drinking Water Protection (DWP) Section of the Minnesota Department of Health (MDH) is coordinating a project in relation to the Unregulated Contaminant Monitoring Rule. Funded by a grant from the Environment and Natural Resource Trust Fund, the program is moving from planning to implementation.

MDH is conducting this study to understand what contaminants are present in Minnesota drinking water resources and to protect the health of Minnesotans. MDH will use the results to set priorities for source water protection and the development of health-based guidance values.

Jane de Lambert, in conjunction with district engineers around the state, has been contacting public water systems to secure their approval for participation. Most systems have elected to participate.

Only community water systems are being sampled.

“While having yet to receive any data, we know from prior work that public water systems and their staff will need assistance in understanding and communicating the results that will be obtained,” said Steve Robertson, MDH Source Water Protection Unit supervisor. “If prior work is any guide, this study’s results will include a large array of non-detections, and may reveal some surprise detections.

“Accordingly, we have started the process of preparing risk management materials to help public water systems use and communicate effectively about the study’s results.”

Go to top

Southern Minnesota Cities Turn to Innovative Methods: New Ulm and Lafayette

New Ulm

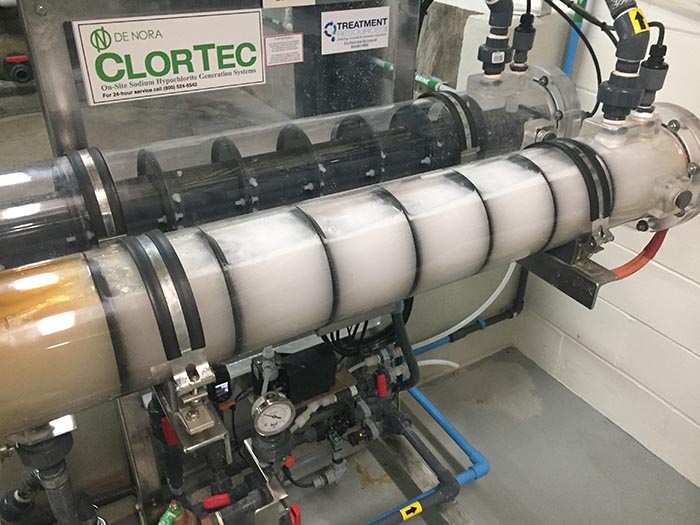

New Ulm's chlorine generator.

George Brown is not only a man about town, he is a man about the Midwest. Born and raised in Iowa, Brown worked in water treatment in Olathe, Kansas, before coming to New Ulm in 1997. Four years later, he went to Valparaiso, Indiana, and, after a dozen years there, turned to teaching water technology at a community college in Salina, Kansas. When the program was discontinued, he returned to New Ulm, taking over as water department supervisor in January 2014.

He has no plans to move again, which is good news to his wife, a native of nearby Danube. Much of what Brown has seen in his travels has stuck with him, none more than a water plant with on-site chlorine generation he visited in South Bend, Indiana.

On-site chlorine generation is a relatively new concept in Minnesota although several cities have adopted it—Burnsville, Baxter, and Fairmont among them. “Safety is the big benefit,” said Brown. Rather than storing chlorine in an adjacent building, New Ulm now produces its own within existing space in its treatment plant.

Soon after Brown returned to New Ulm, the utility began talking to SEH, Inc. of Vadnais Heights, Minnesota, which performed a preliminary engineering report about on-site generation. Minnesota Department of Health (MDH) engineer David Weum reviewed the plans and gave a thumb’s up.

History

New Ulm’s public water supply goes back to the 19th century, with a water main known to have existed as early as 1891. The city had early treatment plants, including a facility on Water Street, near the Minnesota River, that was used to remove iron and manganese until the current plant opened on German Street in 1994. The previous plant had a gravity filter and used ozone for disinfection.

The city is known for Schell’s Brewery, which now uses municipal water for its beer, and New Ulm has several other large commercial customers, including 3M and Heinz, in addition to its 13,000 residents. Its annual daily demand in the summer is 2 million gallons.

New Ulm has 13 wells, 11 of them river-bottom sand-and-gravel wells. The wells are hundreds of feet deep, under a clay layer, and thus not influenced by surface water.

Incoming water is pumped to aerators to enhance the oxidation of iron and manganese. After detention, the water flows into the silica-and-sand filters. New Ulm has five filters, each 528 square feet.

Chlorine is not added as pre-treatment since it would nullify the biological activity in the filters. Biological treatment has long been used on wastewater to stimulate organisms that consume contaminants. The process has gained popularity with water treatment in the 21st century. The central Minnesota city of Hutchinson was one of the first in the state to actively pursue this treatment, although conditions in filters often create natural biological nitrification.

“It’s only recently that water systems began purposely cultivating biologically active filters,” said Jeff Ledin of SEH, Inc. Ledin’s colleague, John Thom, noted that more and more water treatment plants in the state, especially those with ammonia issues, are letting the natural biological activity in filters work for them. “People are figuring it out,” said Thom, who added that the next phase for New Ulm may involve transferring a pilot unit from nearby Lafayette to deal with ammonia.

The generator has two cells, one as a backup. If needed, the cells can be changed within 30 minutes.

Chlorine Addition

Coming off the filters, the water is softened before going into a brine tank, which heats the water to 70 degrees. It then passes through one of two cells at about a gallon a minute, producing about 100 pounds of chlorine per day.

The equipment, which cost $300,000, was installed in November 2018 with the switchover made the following March. Brown said they don’t yet have enough information to compare operating costs with gas chlorine. He said they pay approximately 20 cents a pound for salt and need three pounds of salt, plus two kilowatts of electricity, to make one pound of chlorine.

Beyond the cost, the chlorine being generated is not hazardous. Chief plant operator Joel Johnson said they produce a blended solution of .9 percent concentration, well below the 6 percent in household bleach. They are getting the same residual in the distribution system.

Said Johnson, “We learned that old dogs can still learn to run a plant new style.”

Left to right: Joel Johnson, George Brown, and Jeff Ledin of SEH, Inc. in front of the former wellhouse, which later stored chlorine cylinders.

History of On-Site Chlorine Generation (from Summer 2015 Waterline)

Erin Briggeman of Black & Veatch wrote about the history of on-site sodium hypochlorite generation in a book edited by Black & Veatch Corporation, White’s Handbook of Chlorination and Alternative Disinfectants, 5th edition (copyright 2010 John Wiley & Sons, Inc):

“On-site generation of hypochlorite in the United States was largely inspired by the use of hypochlorite solution during World War I. . . . Its success as an antiseptic for treatment of open wounds led to on-site generation of it in hospitals. . . . Wallace & Tiernan (now part of Evoqua Water Technologies) first made electrolytic chlorinators to provide a safe means of chlorinating swimming pools in buildings where people slept. . . . The chlorinator aroused the interest of Pan American Airways, which, at the time (1936), was establishing refueling sites on its San Francisco-to-Sydney and Orient flights.

“After World War II, the enthusiasm for on-site generation of chlorine disappeared until the hazard potential of chlorine gas stored in containers was evaluated, owing to the proliferation of chlorine gas installations at wastewater and potable water treatment plants. . . . In the 1970s the popularity of on-site generation began to rise once again, largely because of the potential hazards of liquid-gas systems using chlorine stored in containers. . . . Starting in the 1990s, after the advent of the Uniform Fire Code, there has been a great surge in the interest of on-site generation of chlorine. The product is inherently safer because of its lower concentration. . . . Current on-site generation systems produce chlorine solutions containing only 0.8% chlorine, and this concentration is not classified as hazardous.”

Briggeman said more interest in the system was sparked by the terrorist attacks on September 11, 2001. “After the attacks, the risk associated with chlorine gas systems was reevaluated. In addition, with a culture more attuned to risk and safety of operators and surrounding communities, interest in and installation of on-site generation sodium hypochlorite units have seen a significant increase.”

Lafayette

The city of Lafayette has a treatment plant for the water it serves to its 500 residents. Recently the city commissioned a pilot study to enhance its treatment and removal of iron and manganese as well as ammonia.

John Thom of SEH, Inc. studied the biological removal of iron with a pilot unit, and the design was improved by the Minnesota Department of Health. Before Lafayette could implement the new system, it had another issue.

In the fall of 2018, the city had a bypass while doing maintenance on its tower. It opened the pumps to let the water flow freely. During this time, one of the hydrants was inadvertently closed, causing three water breaks and a pressure surge back into the filter, which ruptured the bottom of the filter.

As part of the repair, Lafayette moved forward with the biological treatment project, which included the addition of hollow balls, which serve as a surface for bacteria to grow. (These balls have been used in other cities, including Waite Park, which installed aeration balls with its packing in air stripping towers.)

“The iron, manganese, and ammonia become the food source for the bacteria,” said Thom, and the balls enhance the cultivation of the bacteria.

The balls provide “more room for the bugs to grow, so there is not as much pressure on the filters,” according to operator Rick Timm.

Rick Timm and the aeration balls.

Once it became operational in early 2019, the new process worked well on iron and ammonia, although it needed some adjustments for the manganese. Thom said that he and superintendent Allen Fox, decided “to think like dirty-water guys.” They recycled the filter effluent back to the top of the filter and re-aerated the water. “That removed the manganese,” Thom said.

From here, the pilot unit used for the study may be going to nearby New Ulm as that city considers enhanced biological filtration of ammonia.

Go to top

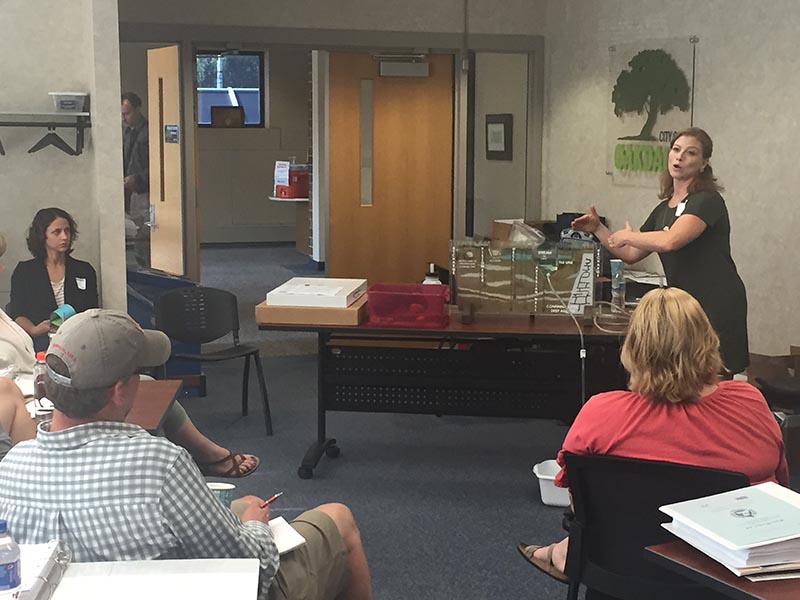

Drinking Water Institute in Oakdale

The annual Drinking Water Institute for Educators was held in August in Oakdale. The Minnesota Department of Health and Minnesota Section of American Water Works Association have been conducting these institutes since 2001. Science teachers from around the state come together and develop action plans to create inquiry-based activities that they can integrate into their existing science curriculum. The 2020 Drinking Water Institute will be August 3-5 in Red Wing. More information: WaterWorks! A Drinking Water Institute for Educators

Go to top

New Brighton Keeps on Pumping

Nearly 40 years later, Bob Benke recalls the “daunting experience” of getting the news of contamination in New Brighton’s water supply. A council member and later a seven-term mayor, Benke was present for an emergency council meeting in the summer of 1981 when the Minnesota Department of Health (MDH) informed the city that trichloroethylene (TCE) and other volatile organic compounds (VOCs) were in its water.

Nearly 40 years later, Bob Benke recalls the “daunting experience” of getting the news of contamination in New Brighton’s water supply. A council member and later a seven-term mayor, Benke was present for an emergency council meeting in the summer of 1981 when the Minnesota Department of Health (MDH) informed the city that trichloroethylene (TCE) and other volatile organic compounds (VOCs) were in its water.

New Brighton responded quickly, sending a letter to all residents within days. It began testing its wells weekly and changed the sequence of well pumping to draw first from those with the least amount of contamination.

Toward that end, New Brighton stopped using wells in the Prairie du Chien and Jordan aquifers, where the contamination existed, and went to wells extending into the deeper Mount Simon-Hinckley formation. It drilled additional deep wells. The city also knew this was a stop-gap measure, not a long-term solution, and it also required the addition of iron-removal devices at some of the wells as water from the deeper aquifer was creating aesthetic problems.

Mayor Bob, as Benke is still known, credits the residents for responding to the need to conserve water. “Education was a big part of it,” he said, noting that the reduced water usage allowed the city to form a long-term plan.

One step was identifying the source of the contamination, which was the Twin Cities Army Ammunition Plant (TCAAP) in adjacent Arden Hills. New Brighton sued the federal government and reached an agreement for the Army to pay for the construction and operation of a water treatment facility. The plant, using granular-activated carbon (GAC), removed the VOCs and also reduced the plume and kept it from migrating.

The remediation goal for the plume meant pumping more water than New Brighton could use, so the city began providing water to Fridley, its neighbor to the west. As part of this water sharing, the utility built an addition to the plant to house equipment to oxidize the water with chlorine and permanganate and a greensand filter to remove iron and manganese.

All seemed under control until 2015 when 1, 4 dioxane (DX), also from TCAAP, was discovered. Once again, the Army agreed to fund an expansion to construct additional treatment.

As an interim measure, the city switched to water from Minneapolis, which has reservoirs only a few blocks from the New Brighton plant, as it prepared for another addition: an advanced oxidation process using ultraviolet (UV) light and hydrogen peroxide (H2O2) to remove the 1, 4 dioxane and other contaminants. “The peroxide, which is fed first, reacts with the UV to create hydroxyl radicals,” explained MDH engineer Lucas Martin, who has worked with New Brighton for years.

“The hydroxyl radicals are a dioxane scavenger. It attacks the 1, 4 dioxane, breaking up DX molecules and converting them into harmless components, such as carbon dioxide and water,” said Eric Volk, who became New Brighton’s public works superintendent in March 2019. He added that the hydrogen peroxide they use is at a 50 percent concentration. “It’s pretty potent. Drug store peroxide has a 3 percent concentration.”

Volk said some excess hydrogen peroxide passes through the process without reacting. “The H2O2 gets catalyzed in the GAC in a reaction that turns the H2O2 into water, H2O, and pure oxygen, O2.”

The advanced oxidation process consists of three reactor trains. Each train has two chambers, and each chamber has two sections with each section containing 72 UV bulbs.

Above: The advanced oxidation has a total of 864 ultraviolet bulbs. Below: The original plant, completed in 1990, consists of 16 granular-activated carbon filters.

The new system went on line in November 2018. The city held an open house a year later to celebrate the return to New Brighton water. Mayor Val Johnson praised city officials from the 1980s and 1990s for their efforts, calling it a “David and Goliath” story of how a small suburb took on the federal government.

Volk said they are still performing normal adjustments on the new treatment, “just tweaking things a bit,” but the system is working well and the dioxane has been reduced to well below health-risk limits.

Mayor Val Johnson at the ceremony in October 2019 to celebrate the treatment plant addition. Photo by Sandra Daniloff

Go to top

MDH Issues Guidance to Operator Exposure of Radon at Water Treatment Plants

Radon is a naturally-occurring gas that has no color, odor, or taste and comes from the breakdown of radium-226. Radon may be released from areas with radium accumulation, soil gases, sludge, or water. It can travel easily through cracks in concrete or poorly sealed doors and disperses quickly into the atmosphere. Radon is commonly found in the basements of many homes in Minnesota.

Radon may also be found in water treatment plants that remove radium, and, as a result, water operators may be exposed to elevated concentrations of airborne radon within the treatment plant. The long-term health risk of breathing radon is lung cancer.

Check Existing Conditions

Water treatment plants should be tested for airborne radon, particularly if the treatment plant meets at least one of the following conditions:

- Open detention tanks, filters, backwash basins, or clearwells within the treatment plant

- Backwash waste discharged within the treatment plant (sump)

- Accumulation of radium on filter media or sludge (produces radon as a daughter product)

Measure Risk

Radon detectors (long-term alpha track detectors) are available free of charge from the Minnesota Department of Health for testing at treatment plants. Two radon detectors should be left in place for at least three months during testing. These detectors should be placed near each other, at a normal breathing level, away from walls, and in an area where the water operator spends most of his or her time, such as an office or work area. If the source or treatment plant design changes in the future, the water system may want to retest for radon.

If the radon result is less than 4 picocuries per liter (pCi/L), the treatment plant meets the U. S. Environmental Protection Agency’s recommended standard for radon in homes, and the amount of occupational exposure may be limited. If the result is greater than 4 pCi/L, the plant supervisor may contact MDH for information on additional testing.

Reduce Exposure

A significant amount of exposure may occur both during the backwash cycle and throughout the day. Listed below are several recommendations to help to reduce water operator exposure to radon in treatment plants.

- Provide adequate ventilation continuously or when the operator is in the treatment plant.

- Use an exhaust fan located directly above the backwash sump during the backwash cycle.

- Keep the backwash sump in a well-ventilated room separate from the rest of the plant.

- Minimize radium accumulation on filter media by replacing or cleaning filter media.

- Limit time spent in the plant during or shortly after the backwash cycle, or use automatic backwash controls.

A radon test kit costs between $5 and $30, depending on the type of kit. Some test kits may also require an analysis fee paid after mailing the kit to the lab. Options include:

- Air Chek, Inc. a manufacturer of short term & radon test kits. Minnesota residents receive a discount.

- Radonova, a manufacturer of long term radon gas test kits. Minnesota residents receive a discount.

- Local contacts, which are usually affiliated with local city or county health departments. They distribute radon information and/or radon test kits to local residents, See Local Radon Contacts.

Contact MDH compliance engineer Anna Schliep, anna.schliep@state.mn.us, 651-201-4667 to obtain information about occupational exposure and testing for radon.

Radon and Operator Safety in Drinking Water Treatment Plants

Go to top

Professional Operator Development Course Set for Early 2020

The Minnesota Section of American Water Works Association will hold an eight-week Professional Operator Development Course starting Tuesday, January 28 and running until March 18. The course will be held every Tuesday from 7:30 a.m. to 2:30 p.m.

The course is designed to build knowledge of public water systems for the operations and management of any water utility in Minnesota.

Subjects covered include math, filtration, disinfection, sampling, regulations, source water, water quality, and membrane & ion exchange.

Professional Operator Development

Go to top

New Addresses for Minnesota Department of Health Water Websites

The Minnesota Department of Health has moved its web files to a new server. Be sure to update your bookmarks. The main MDH drinking water page is at:

Go to top

MDH to Reduce Printed Copies of Waterline

The Minnesota Department of Health will be reducing the number of printed copies of the Waterline. In addition to the printed copies, the Waterline is on-line.

The archives on this site include links to newsletters from the previous three years.

Many subscribers have opted out of print versions and read it on-line after getting an email notification and link when a new one is issued.

If you would like to receive the Waterline in this manner, sign up here:

Minnesota Department of Health Email Updates: Waterline

Past Newsletters Archived at wateroperator.org

The Minnesota Department of Health is archiving past issues of the Waterline for only the previous three years. However, wateroperator.org is hosting past issues back to 1997.

To access these, go to Search for Documents. Select the following filter criteria: HOST – Minnesota Department of Health; TYPE – Newsletters/Magazines; STATE – Minnesota. Click the “Retrieve Documents” button.

Go to top

Reminder to All Water Operators

When submitting water samples for analyses, remember to do the following:

- Take coliform samples on the distribution system, not at the wells or entry points.

- Write the Date Collected, Time Collected, and Collector’s Name on the lab form.

- Attach the label to each bottle (do not attach labels to the lab form).

- Include laboratory request forms with submitted samples.

- Do not use a rollerball or gel pen (the ink may run).

- Consult your monitoring plan(s) prior to collecting required compliance samples.

Notify your Minnesota Department of Health district engineer of any changes to your systems.

If you have questions, call the Minnesota Department of Health contact on the back of all sample instruction forms.

Calendar

Operator training sponsored by the Minnesota Department of Health and the Minnesota AWWA will be held in several locations this spring.

Register for schools and pay on-line:

Go to top