Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Chanhassen Enhances Aesthetics of Water and Community

From the Spring 2019 Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

Ten years ago, before million-dollar mansions began dotting the landscape on the western side of Chanhassen, the city purchased property and posted it as the future site of a water treatment plant. That didn’t assuage the angst of incoming residents, who were vocal about how a water plant would affect the look of the neighborhood. Working together, Chanhassen and the homeowners association developed a plan for a facility that blended in with prairie-themed architecture and landscaping. The pleasing aesthetics apply to more than just the water plant; the residents of the higher elevations of the city are getting better looking and tasting water, thanks to the treatment to remove iron and manganese from the water.

Chanhassen is another of the growing outer ring of Twin Cities suburbs that is constantly keeping up with the increasing number of residents. Into the early part of the 21st century, the city was able to supply safe water to its citizens with the addition of chlorine and fluoride at its five wells.

In 2006 Chanhassen opened its first water treatment plant, which removed iron and manganese. Located on the eastern edge of the city, the plant serviced the low pressure zone, which wrapped around the higher portions of Chanhassen, leaving an enclave on the west side that did not receive treated water. Within this area, the city owned land and had plans to build a second treatment plant.

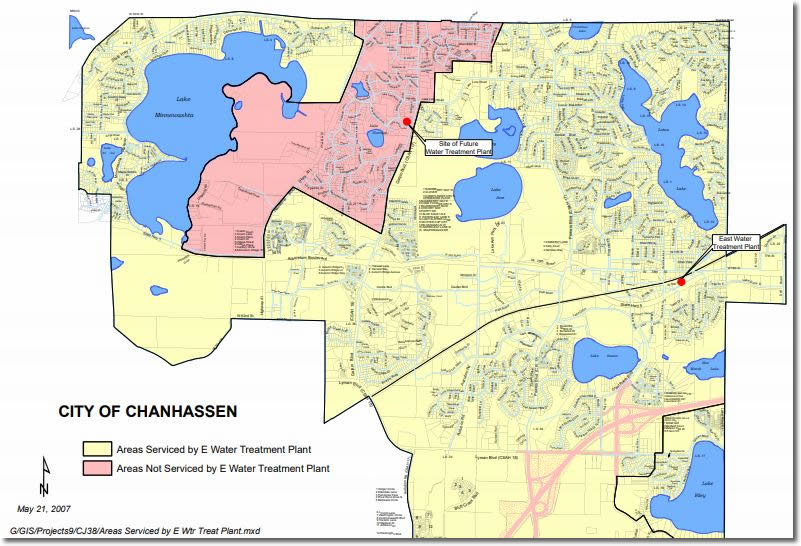

A 2007 map, produced shortly after the east treatment plant was constructed, shows the areas served and not served by the plant. The shaded area toward the left and top shows the site of the west treatment plant and the area now served by it.

Before this happened, the surrounding area was being filled with large homes, along with residents who became concerned about having a utilitarian facility in their midst. The city and its engineering firm, WSB & Associates, Inc. of St. Paul, moved forward with plans for a water treatment plant while also meeting with representatives of the homeowners association in the Lake Harrison neighborhood. Greg Johnson, manager of WSB’s water/wastewater group, said one of the representatives was an architect who had ideas about the design of the plant.

Eventually, the parties settled on a prairie-themed look for the building and the grounds that was satisfactory to all involved. The facility was built into a hillside, which required a great deal of earth moving, although it provides a pleasing appearance and partially camouflages some elements of the facility.

Construction on the west treatment plant.

City engineers Paul Oehme and George Bender pointed out how the backwash holding tank was built into hill, some below ground with part projecting over it, surrounded by a rock wall that blends in with the exterior of the building. A hill over one side of the tank has 13 feet of styrene blocks over the tank, rather than soil, to save on structural reinforced concrete costs.

The backwash holding tank is partially surrounded by the rock wall on the right.

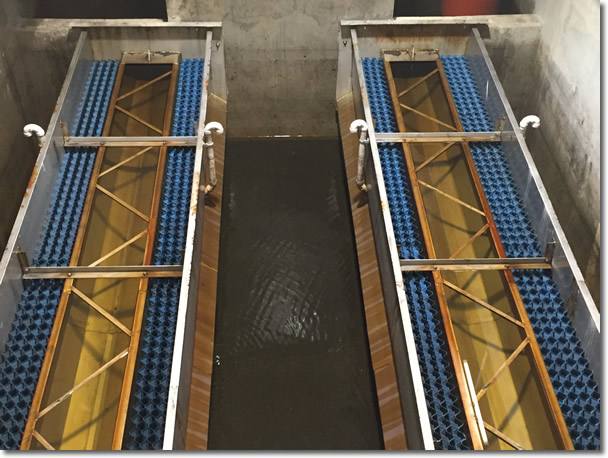

Johnson said they used pilot testing to come up with a design for pressure aeration, detention, and gravity filters. The main difference between the new plant and the east water treatment plant is the addition of a detention tank. Incoming water is fed air with chlorine for the oxidation of iron in the detention tank. Sodium permanganate is added to oxidize manganese. The water rises and falls over baffles and then a weir, getting 15 minutes of detention. “The water flows like a waterfall,” said Bender.

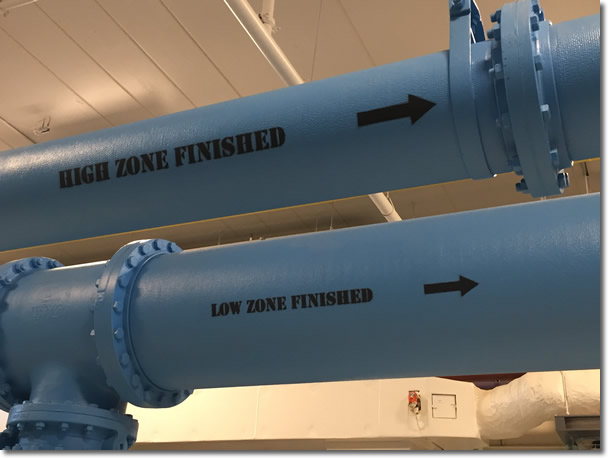

After detention, the water splits before reaching the filters, which consist of two banks of three anthracite greensand filters each. Both the east and west plants pump into the low-pressure zone, the main zone in the city. The west plant is able to service the higher areas and has been oversized for the ultimate buildout of the community. “This plant straddles the high and low zone,” said utility superintendent Kevin Crooks. “We’re set.”

Water from the west treatment plant is sent to the high and low service zones.

As construction was beginning in mid-2017, the utility began feeding orthophosphate into the system for corrosion control. Doing so avoided potential problems with lead and copper. Oehme said this was one of the lessons they learned from their experiences with construction of the first treatment plant.

The plant can produce nine million gallons per day. It was designed to account for anticipated growth. Chanhassen’s population is currently 24,000 and is projected to be 35,000 by 2040. An additional challenge is dealing with large seasonal swings in demand. Because of high residential irrigation during the warmer months, the utility uses three-and-a-half times more water in the summer than in the winter.

One of six filters in the west treatment plant.

Chanhassen bonded for this project and included it as part of long-term rate planning. The total project cost approximately $16.5 million, which includes the treatment plant, engineering, water-main improvements, and chemical equipment.

The west treatment plant went on-line August 3, 2018. The city performed frequent flushing in the early stages to deal with discoloration issues that are common with such projects. Oehme said they’ve gotten a few calls about the initial issues with the water and are pleased that they are getting increasing feedback from residents about the improved quality of the water.

Simon McCormack, the district engineer for the Minnesota Department of Health, hailed the city’s efforts to connect stand-alone wells to the treatment plant and come up with a design that works for the neighbors. “This is a prime example of community collaboration in action,” he said.

Go to top

Of Interest

Pumphouses Designed for Function as Well as Attractiveness

Hastings Removes Nitrate with New Plant