Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Southern Minnesota Cities Turn to Innovative Methods: New Ulm and Lafayette

From the Waterline

Quarterly Newsletter of the Minnesota Department of Health Public Water Supply Unit, Waterline

A complete list of feature stories can be found on the Waterline webpage.

The south-central Minnesota cities of New Ulm (right) and Lafayette (left) are going to relatively new methods of dealing with iron, manganese, and ammonia. They may also be sharing technology as a pilot unit installed in Lafayette to examine biological filtration may be moving to the New Ulm plant.

New Ulm

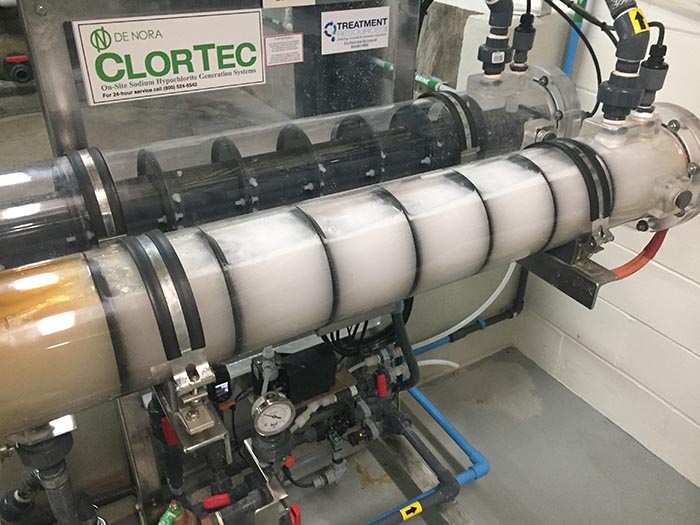

New Ulm's chlorine generator.

George Brown is not only a man about town, he is a man about the Midwest. Born and raised in Iowa, Brown worked in water treatment in Olathe, Kansas, before coming to New Ulm in 1997. Four years later, he went to Valparaiso, Indiana, and, after a dozen years there, turned to teaching water technology at a community college in Salina, Kansas. When the program was discontinued, he returned to New Ulm, taking over as water department supervisor in January 2014.

He has no plans to move again, which is good news to his wife, a native of nearby Danube. Much of what Brown has seen in his travels has stuck with him, none more than a water plant with on-site chlorine generation he visited in South Bend, Indiana.

On-site chlorine generation is a relatively new concept in Minnesota although several cities have adopted it—Burnsville, Baxter, and Fairmont among them. “Safety is the big benefit,” said Brown. Rather than storing chlorine in an adjacent building, New Ulm now produces its own within existing space in its treatment plant.

Soon after Brown returned to New Ulm, the utility began talking to SEH, Inc. of Vadnais Heights, Minnesota, which performed a preliminary engineering report about on-site generation. Minnesota Department of Health (MDH) engineer David Weum reviewed the plans and gave a thumb’s up.

History

New Ulm’s public water supply goes back to the 19th century, with a water main known to have existed as early as 1891. The city had early treatment plants, including a facility on Water Street, near the Minnesota River, that was used to remove iron and manganese until the current plant opened on German Street in 1994. The previous plant had a gravity filter and used ozone for disinfection.

The city is known for Schell’s Brewery, which now uses municipal water for its beer, and New Ulm has several other large commercial customers, including 3M and Heinz, in addition to its 13,000 residents. Its annual daily demand in the summer is 2 million gallons.

New Ulm has 13 wells, 11 of them river-bottom sand-and-gravel wells. The wells are hundreds of feet deep, under a clay layer, and thus not influenced by surface water.

Incoming water is pumped to aerators to enhance the oxidation of iron and manganese. After detention, the water flows into the silica-and-sand filters. New Ulm has five filters, each 528 square feet.

Chlorine is not added as pre-treatment since it would nullify the biological activity in the filters. Biological treatment has long been used on wastewater to stimulate organisms that consume contaminants. The process has gained popularity with water treatment in the 21st century. The central Minnesota city of Hutchinson was one of the first in the state to actively pursue this treatment, although conditions in filters often create natural biological nitrification.

“It’s only recently that water systems began purposely cultivating biologically active filters,” said Jeff Ledin of SEH, Inc. Ledin’s colleague, John Thom, noted that more and more water treatment plants in the state, especially those with ammonia issues, are letting the natural biological activity in filters work for them. “People are figuring it out,” said Thom, who added that the next phase for New Ulm may involve transferring a pilot unit from nearby Lafayette to deal with ammonia.

The generator has two cells, one as a backup. If needed, the cells can be changed within 30 minutes.

Chlorine Addition

Coming off the filters, the water is softened before going into a brine tank, which heats the water to 70 degrees. It then passes through one of two cells at about a gallon a minute, producing about 100 pounds of chlorine per day.

The equipment, which cost $300,000, was installed in November 2018 with the switchover made the following March. Brown said they don’t yet have enough information to compare operating costs with gas chlorine. He said they pay approximately 20 cents a pound for salt and need three pounds of salt, plus two kilowatts of electricity, to make one pound of chlorine.

Beyond the cost, the chlorine being generated is not hazardous. Chief plant operator Joel Johnson said they produce a blended solution of .9 percent concentration, well below the 6 percent in household bleach. They are getting the same residual in the distribution system.

Said Johnson, “We learned that old dogs can still learn to run a plant new style.”

Joel Johnson, George Brown, and Jeff Ledin of SEH, Inc. in front of the former wellhouse, which later stored chlorine cylinders.

History of On-Site Chlorine Generation (from Summer 2015 Waterline)

Erin Briggeman of Black & Veatch wrote about the history of on-site sodium hypochlorite generation in a book edited by Black & Veatch Corporation, White’s Handbook of Chlorination and Alternative Disinfectants, 5th edition (copyright 2010 John Wiley & Sons, Inc):

“On-site generation of hypochlorite in the United States was largely inspired by the use of hypochlorite solution during World War I. . . . Its success as an antiseptic for treatment of open wounds led to on-site generation of it in hospitals. . . . Wallace & Tiernan (now part of Evoqua Water Technologies) first made electrolytic chlorinators to provide a safe means of chlorinating swimming pools in buildings where people slept. . . . The chlorinator aroused the interest of Pan American Airways, which, at the time (1936), was establishing refueling sites on its San Francisco-to-Sydney and Orient flights.

“After World War II, the enthusiasm for on-site generation of chlorine disappeared until the hazard potential of chlorine gas stored in containers was evaluated, owing to the proliferation of chlorine gas installations at wastewater and potable water treatment plants. . . . In the 1970s the popularity of on-site generation began to rise once again, largely because of the potential hazards of liquid-gas systems using chlorine stored in containers. . . . Starting in the 1990s, after the advent of the Uniform Fire Code, there has been a great surge in the interest of on-site generation of chlorine. The product is inherently safer because of its lower concentration. . . . Current on-site generation systems produce chlorine solutions containing only 0.8% chlorine, and this concentration is not classified as hazardous.”

Briggeman said more interest in the system was sparked by the terrorist attacks on September 11, 2001. “After the attacks, the risk associated with chlorine gas systems was reevaluated. In addition, with a culture more attuned to risk and safety of operators and surrounding communities, interest in and installation of on-site generation sodium hypochlorite units have seen a significant increase.”

Lafayette

The city of Lafayette has a treatment plant for the water it serves to its 500 residents. Recently the city commissioned a pilot study to enhance its treatment and removal of iron and manganese as well as ammonia.

John Thom of SEH, Inc. studied the biological removal of iron with a pilot unit, and the design was improved by the Minnesota Department of Health. Before Lafayette could implement the new system, it had another issue.

In the fall of 2018, the city had a bypass while doing maintenance on its tower. It opened the pumps to let the water flow freely. During this time, one of the hydrants was inadvertently closed, causing three water breaks and a pressure surge back into the filter, which ruptured the bottom of the filter.

As part of the repair, Lafayette moved forward with the biological treatment project, which included the addition of hollow balls, which serve as a surface for bacteria to grow. (These balls have been used in other cities, including Waite Park, which installed aeration balls with its packing in air stripping towers.)

“The iron, manganese, and ammonia become the food source for the bacteria,” said Thom, and the balls enhance the cultivation of the bacteria.

The balls provide “more room for the bugs to grow, so there is not as much pressure on the filters,” according to operator Rick Timm.

Rick Timm and the balls.

Once it became operational in early 2019, the new process worked well on iron and ammonia, although it needed some adjustments for the manganese. Thom said that he and superintendent Allen Fox, decided “to think like dirty-water guys.” They recycled the filter effluent back to the top of the filter and re-aerated the water. “That removed the manganese,” Thom said.

From here, the pilot unit used for the study may be going to nearby New Ulm as that city considers enhanced biological filtration of ammonia.

Go to > top.

Of Interest

Biological Filtration Used in New Hutchinson Water Plant

Burnsville Becomes First Metro System with On-Site Hypochlorite Generation

Schell's Starts with the Water

Waite Park Uses Air Strippers to Restore “Lots and Lots” of Good Water