Drinking Water Protection

- Drinking Water Protection Home

- About Us

- A-Z Index of Contaminants in Water

- Community Public Water Supply

- Drinking Water Grants and Loans

- Drinking Water Institute

- Drinking Water in Schools and Child Cares

- Drinking Water Revolving Fund

- Laws and Rules

- Noncommunity Public Water Supply

- Source Water Protection

- Water Operator and Certification Training

- Drinking Water Protection Contacts

Related Topics

- Annual Reports

- Drinking Water Risk Communication Toolkit

- Drinking Water Protection External Resources

- Fact Sheets

- Forms

- Invisible Heroes Videos: Minnesota's Drinking Water Providers

- Noncom Notes Newsletter

- Sample Collection Procedures (videos, pictures, written instructions)

- Waterline Newsletter

Related Sites

- 10 States Standards

- Clean Water Fund

- Health Risk Assessment – Guidance Values and Standards for Water

- Minnesota Well Index

- Water and Health

- Wells and Borings

Environmental Health Division

Waterline: Winter 2023 - 2024

Editor:

Stew Thornley

Editor:

Noel Hansen, Erin Culver, Bob Smude

Subscribe to The Waterline newsletter. An e-mail notice is sent out each quarter when a new edition is posted to the web site.

On this page:

- Minneapolis wins State Fair Tap Water Taste Test

- Education in Minneapolis

- SDWA video updated for 50th anniversary

- What's shaking at MDH?

- Cold Spring opens first treatment plant in state to treat nitrate biologically

- NE Ohio Regional Sewer District provides important election information

- MRWA offers apprenticeship program

- DWRF funds the North Shore

- When your water tower is down

- MDH proposing updates to health risk limits rules

- Public Health Priority Points Information

- Professional Operator Development program announces new course for 2024

- Quote of the quarter (and other gems)

- Reminder to all water operators

- Calendar

Minneapolis wins State Fair Tap Water Taste Test

Minneapolis won the Great Minnesota State Fair Tap Water Taste Test, held on the Sustainability Stage of the EcoExperience building at the State Fair August 24. St. Cloud was the runner-up while LeSueur finished third and Moorhead fourth. Past champions of the taste test are Golden Valley, International Falls, Fairmont, St. Cloud, Lake Elmo, Chaska, Crookston, and Saint Peter.

Below, Smiling Bert Tracy (on the right) looks on as WCCO Radio host Jason DeRusha (on the left) talks about the contest and high quality of Minnesota water with a committee member later that day.

Go to top

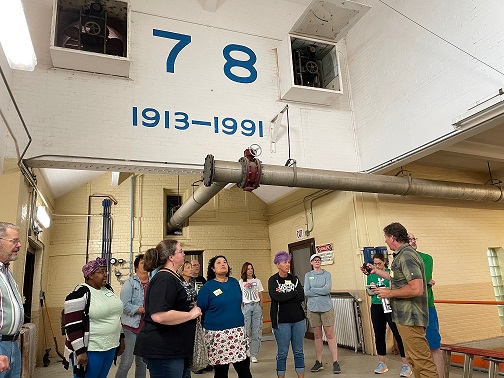

Education in Minneapolis

Minneapolis Water Works hosted educational activities at two of its locations in August. Above, in Columbia Heights, teachers attended the Drinking Water Institute and got to see the old filter plant, which had been used through 1993. The teachers participated in interactive exercises in the lobby of the ultrafiltration plant with the membranes shown behind them. The Drinking Water Institute, in which Minnesota science teachers learn about water and develop ways to incorporate it into their existing curriculum, has been held since 2001. Next year it will be at St. Paul Regional Water Services from July 29 to 31.

In mid-August Minneapolis held a pair of two-day workshops on filter survelliance for their operators and supervisors. Conducted by Hazen and Sawyer of St. Paul and held at the utility’s filter plant in Fridley, the training consisted of classroom presentations and hands-on training to examine filter conditions for the purpose of optimizing operations and backwashing. In the photo below, Ken Funt and Eric Pederson perform turbidity analysis on backwash water.

Go to top

SDWA video updated for 50th anniversary

Ten years ago, an anniversary video was made to celebrate 50 years of the federal Safe Drinking Water Act, featuring appearances by Al Quie (shown above) and Walter Mondale, who were in Congress when the act was passed.

50th anniversary Safe Drinking Water Act video

The 40-year anniversary got more than 28,000 views and is still on-line.

40th anniversary Safe Drinking Water Act video

Go to top

What's shaking at MDH?

Kylie Jacobsen (above) has joined the Drinking Water Protection (DWP) Section as a strategic initiatives and communications coordinator. She will be working on activities related to source water protection, Clean Water Fund projects, and outreach efforts.

Spouse- and child-free, Kylie has two cats, Bean and Yogi.

She is from the Twin Cities and is back after seven years in Madison, Wisconsin (retaining her fandom for the Vikings and Gophers rather than the Packers and Badgers). Her background is in public health and science communication. Most recently, Kylie was managing nutrition security programs with Second Harvest, a Feeding America foodbank.

She adds, “I love all things outdoors, particularly rock climbing and exploring national parks. I’m also a big foodie who loves cooking, baking, and trying new restaurants.”

Janelle Ruth has joined DWP as a management analyst working primarily in the Minnesota Drinking Water Information System. Janelle grew up in Apple Valley and got her degree in earth sciences with an emphasis on hydrogeology at the University of Minnesota. Before joining MDH, she worked for Dakota County’s Groundwater Protection Unit, managing the Well Sealing Grant program. She also has experience working as an environmental consultant and as a hazardous waste laboratory technician. As a huge animal lover, Janelle has also volunteered with multiple animal rehabilitation/wildlife organizations, during which she routinely fed black bears and a variety of baby birds. In her spare time, she enjoys snuggling with her bunny, painting, and playing board games.

Johanna Hayden is the new communications and strategic initiatives specialist in the Minnesota Department of Health DWP Section. A native of Dallas (and a Cowboys fan, of course), she has lived and worked in Germany and Miami in addition to the Texas towns of Dallas and Austin. She loves to travel and has been to 29 countries. With a master’s degree in neuroscience/neuropsychology, Johanna was worked in education as a teacher and in corporate communications with FEMA, the Department of Defense, and biotech industries.

Johanna is married to her high school sweetheart, Ian, and they have four children (ages 6 to 19) and one very opinionated Yorkie. Johanna says, “We decided to relocate our family to Minnesota after seeing the incredible natural beauty, the wonderful people, and the way that this state is committed to creating better lives for all its citizens. We have been here just under a year and couldn’t be happier. Thank you Minnesota for welcoming us with open arms!”

Sam Swanson is a compliance engineer in the CPWS Unit. Born and raised in St. Paul, he went to college in Rochester, New York, and got a bachelor’s degree in chemical engineering. His studies included a Photography in Cuba course, which took him to Cuba for two weeks taking pictures. He also worked his way through the YMCA Camp Menogyn program, which included a six-week canoe and camping trip through the Arctic, all the way up to Nunavut in Canada. Sam also enjoys playing chess and reading science fiction.

David Rindal has returned to the Community Public Water Supply (CPWS) Unit after an absence of more than two years following a serious injury.

Karla Peterson, previously the supervisor of the CPWS Unit at the Minnesota Department of Health (MDH), has become the chief engineer and technical advisor for MDH’s Drinking Water Protection Section. She will be the principal technical authority for all aspects of engineering and operations for public water systems.

Andrew Karp is now the engineer for the Metro-South District, succeeding Jessie Kolar, who moved to the Infrastructure Unit

Go to top

Cold Spring opens first treatment plant in state to treat nitrate biologically

Known for beer and baseball, the central Minnesota city of Cold Spring relies on a steady supply of safe drinking water to keep its businesses humming and its 4,000 residents hydrated. Cold Spring is typical in this regard, its most important resource not being its most prominent. And like other townships and cities in the area, Cold Spring is surrounded by farms and the corresponding challenges agriculture brings to its aquifers, often seen through rising nitrate levels in water.

However, Cold Spring employees note that the issues are a result of more than farming and fertilizers. Public works director Jon Stueve said that agriculture was more of a problem historically than now. “The Department of Ag [Minnesota Department of Agriculture] has done a lot, especially in this area, with the farmers, and they regulate what they do put on the fields. There is a lot of participation from our farmers. They’re doing all they can.”

Tanya Schmidt, the city’s water and wastewater supervisor, echoed Stueve’s sentiments. “When the new generation [of farmers] comes in, you can see it. I grew up on a farm, and I can see the difference when you get the younger generation coming in,” she said before touching on the primary issue they face. “It’s tough geology here.”

Cold Spring has four wells ranging from 63 to 125 feet deep that draw from Quaternary Water Table aquifer. The city has stayed below the maximum contaminant level of 10 parts per million (ppm) for nitrate and was able to keep the level around 5 ppm by blending the wells. Nevertheless, there was a desire to bring the nitrate down even more.

The first approach involved looking for different water sources, according to Ryan Capelle of Stantec, a Minneapolis engineering firm that studied Cold Spring’s options. Quickly determining that treatment would be necessary, Stantec partnered with the city and AdEdge Water Technologies, LLC of Duluth, Georgia, on a pilot study with input and guidance from the Minnesota Department of Health (MDH).

Ion exchange is a common technique for reducing nitrate, but Capelle cited operational issues, particularly the waste stream it would create, as a drawback. Other technologies have been emerging, including one that has been a staple in wastewater treatment: biological filtration. Bacteria has long been used to consume waste materials in water.

In 2007, Hutchinson became the first Minnesota city to use the process for drinking water. Eric Meester, an engineer on the Hutchinson project, said that the longtime success of chemicals for treating drinking water caused resistance to alternative technologies, adding, “The success of chemical treatment has been documented for a long time. Biological removal has occurred naturally for longer, but no one looked for it or why it existed.”

While Hutchinson chose bacteria to treat for iron and manganese and others have used it to reduce ammonia in the water, Cold Spring became the first in the state to use it for nitrate removal. It was “a willingness of Jon and Tanya to be pioneers that opened the door to look at treatment under a new light,” said Capelle. Timing was a factor, too, with the city getting $4 million in a 2018 state bonding bill. “The technology emerged at the right time,” added Capelle. “People were willing to embrace it.”

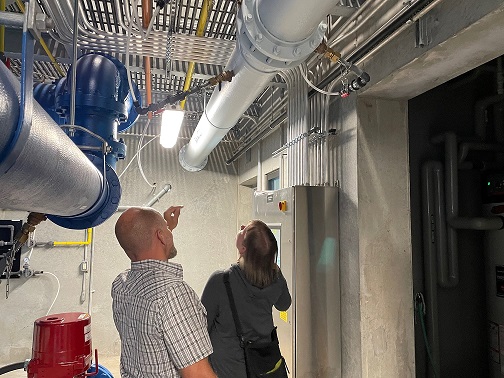

The pilot study began in 2018 in the bottling facility of Cold Spring Brewing Company, adjacent to the city’s wells and the site of the new plant, which went on-line in May 2023. A two-stage fixed-bed biological treatment system, the process is efficient operationally in addition to being environmentally friendly.

Above: Jon Stueve and Ryan Capelle in front of the filters.

Below: Capelle points out the direction of the incoming water to Maria Spitael of the Minnesota Department of Health.

The two-stage process starts in a pressure filter with granular activated carbon (GAC) “This is where the magic happens,” said MDH engineer Brian Noma. The filter is where the denitrifying bacteria live in anoxic (low oxygen) conditions. Acetic acid is added as a carbon source and phosphoric acid as a nutrient. “This creates a favorable environment for the microbes to flourish,” explained Capelle. “This makes them hungry, makes them want to eat the nitrate in Stage 1.

“And now the nitrate is all virtually removed. We then add oxygen with peroxide. We are reoxygenating on the way to stage 2.” The second filter, consisting of 30 inches of GAC on top of 20 inches of sand, removes the excess biomass, in essence polishing the water.

Any of the four wells can go directly to the clearwell or through the plant. “It’s about a 50-50 split,” Capelle said, describing it as a header-type system to blend with any given well and produce 500 treated gallons per minute.

Chlorine is available at the front end of the clearwell, fed at a low dose after treatment. “We don’t want to overchlorinate because that is our source for backwash water,” Capelle said. “We don’t want the backwash water to kill the microbes, so we want the chlorine residual to be low, but not nonexistent at this point.”

The $6 million project included a pipe gallery, additional clearwell capacity, a laboratory and control room, and a large chemical room that allows them to buy in bulk, according to Steuve.

The results have been as desired, the finished water coming out with under 5 ppm, less than half of the MCL.

Photos of the pipe gallery and the top of the pressure filters.

Go to top

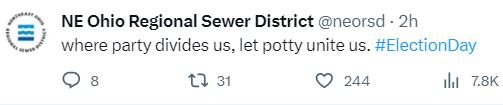

NE Ohio Regional Sewer District provides important election information

The X/Twitter account for the Northeast Ohio Regional Sewer District is always a source of relevant information on important and topical issues.

On November 7, it provided a cogent and inspirational reminder to vote.

Go to top

MRWA offers apprenticeship program

The Minnesota Rural Water Association (MRWA) is offering a registered apprenticeship program. Approved by the Minnesota Department of Labor and Industry, the program provides formal training in the industry.

The two-year apprenticeship program, which can be reduced and broken into three six-month periods for those with a Class D water/wastewater license, has been an initiative of the National Rural Water Association for direct entry and training into the workforce. Interested parties may go to the NRWA website.

Those with questions may contact Joel Jasmer of MRWA, 218-671-3475.

Go to top

DWRF funds the north shore

From south to north (or more specifically, southwest to northeast), Duluth and Two Harbors are the first two Minnesota cities to draw water from Lake Superior. With an Ojibwe name of Gitche Gumee (just ask Henry Longfellow, or Gordon Lightfoot for that matter, if you don’t believe it), Superior is the largest freshwater lake in the world. In addition to Duluth and Two Harbors, it is the water supply for Beaver Bay, Silver Bay, Grand Marais, smaller cities along the north shore. As the two largest cities supplied by the big lake, Duluth (above left) and Two Harbors (above right) have also been regular recipients of money from the state Drinking Water Revolving Fund (DWRF) and both have been putting it to good uses lately.

Duluth - Conquering the city

Nearly $4 million ($3,857,531 to be exact) of DWRF money has helped Duluth install new pumps at its booster station, a structure that goes back to the 19th century and that is flanked by a 14-million-gallon reservoir that is young by comparison, having been rebuilt in 1922.

Duluth has a lake-to-hill geographic profile. The first few inland blocks are flat, but the topography quickly becomes hillside, rising abruptly and steeply. For much of the city’s history, an incline served residents needing to go back and forth in an up-and-down manner.

Lake Superior is approximately 600 feet above sea level, the lowest part of Minnesota. The elevation change between the utility’s intake and adjacent treatment facility on the lake is about 280 feet to the booster station. From there the water travels upward through two other reservoirs and two other pump stations, eventually climbing 950 feet above Lake Superior to the Highland tower, the highest point in Duluth’s water system, supplying Duluthians along the way as well as the consecutive systems of Hermantown and Rice Lake. In all, Duluth has eight major pressure zones and a handful of smaller ones.

Duluth’s Aaron Soderlund said the new pumps are only the fourth set in the history of the booster station. The three pumps, he explained, usually run one at a time at 3,300 gallons per minute (gpm). They can get up to 5,000 gpm with two pumps running but rarely do. “The problem with getting up to those flow rates is our pressures,” Soderlund added.

The pumps and surge tank in the Duluth booster station.

The pumps are on the same spots as the previous ones although the new pipes are underneath the building. Another change was the addition of a surge vessel with a bladder tank. Soderlund said they considered the need for a quick shutoff of the pumps in case of a power interruption. “We had some issues in the upper end of this zone, where we would have negative pressure, so the surge vessel is to handle the surge coming back from the stations to alleviate those problems.”

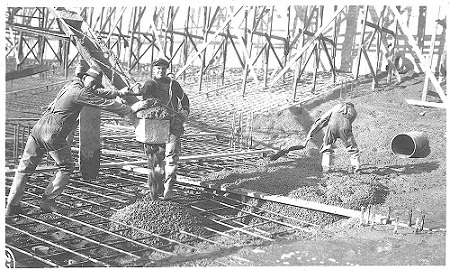

The booster station, shown in the 1930s, had a gas lantern on the front. The mounting is still visible behind Corey Mathisen, Sabrina Sutter, and Chad Kolstad of the Minnesota Department of Health and Aaron Soderlund of Duluth.

The pump project began in early 2022 and went on-line in stages. A challenge encountered along the way was with two suction lines, one coming in off the street and the other directly from the reservoir. Just outside the booster station is an original valve, which hooks up to the station. More than 130 years old, the valve didn’t work. A diver from AMI Consulting Engineers of Superior, Wisconsin, went into the reservoir to plug a 20-inch intake line to allow for the installation of a new valve.

“We needed to close the valve to put in our suction piping for the new pump,” said Soderlund. “We couldn’t close the valve to isolate off the reservoir to do our work within the station.” The diver put in a ball to plug the intake line long enough to put in the new valve and then complete the suction piping to a new pump. Soderlund said that during the six-to-eight hours it took, “The only thing we had from emptying the 14 million gallons out of that reservoir was that plug.

“That was nerve wracking to say the least.” The challenges surmounted, Duluth completed the work in 2023.

The city’s incline to elevate people was phased out with the coming of new-fangled contraptions such as the automobile. But the transport of water upward is still performed with the same methods that have served Duluth well for more than 100 years.

Installation of the 20-inch suction pipe in 1922 and a look at it from within the reservoir a century later.

Two Harbors - The project that keeps on giving

With DWRF money allocated in 2015 with the rehabilitation of a building housing high-service pumps, Two Harbors continued to benefit from the funding in replacing its chlorine contact facility several years later.

Located about 25 miles northeast of Duluth, Two Harbors came together from the communities of Agate Bay and Burlington, each of which has a bay formed by a southern-jutting promontory.

Two Harbors has had water facilities on Burlington Bay for more than 70 years with a power plant existing on the site even before that. A chlorine contact tank was added in 1958 and a filtration plant about 20 years later. High service pumps, which were replaced in 2016, have been around at least as long as the contact tank.

Bolton & Menk, Inc., began working with Two Harbors in 2016 with the rehabilitation of the high-service pump building. During the project, leaking water was discovered from the chlorine contact tank. Brian Guldan of Bolton & Menk said they installed a drain tile as a temporary fix and put a complete replacement of the tank on their to-do list.

It began getting done a few years later, starting with the demolition of the parking lot south of the existing chlorine contact tank. Space restrictions didn’t allow for construction of the new tank until at least part of the lot was removed. “They are building half of the new one,” said Guldan in the fall of 2023. “The new one will go on-line and get tested, and then the old tank will be demolished and the project completed.” Even with one tank at a time during construction, the flow rates can be adjusted to ensure proper contact time.

After the old chlorine contact tank is removed, they will build a second tank next to the new chlorine contact tank, giving the plant two independent tanks with pump chambers to allow for half the tank to be taken out of service for maintenance and still have the capability to produce water at half the capacity.

Above: Dan Foster and Brian Guldan of Bolton & Menk flank Chad Kolstad of the Minnesota Department of Health atop the intake structure on Burlington Bay of Lake Superior. Below: Construction on the chlorine contact tank.

The water treatment facilities have the bay and Lake Superior as a scenic backdrop. The previous contact tank partially blocked the view of the water for nearby residents, who were thrilled to learn that the new structure will be lower, affording an unobstructed vista.

Not just neighbors are enjoying the view. The treatment plant is south of Lakeview Park, which has a trail that is popular with visitors, leading to questions of how to keep people off the new contact tank. One night, Guldan discussed the situation with Chad Kolstad of the Minnesota Department of Health and Luke Heikkila, then the city’s water superintendent. Heikkila said, “Why don’t we turn it into a lookout?”

After Kolstad said he had no problems with the idea, Heikkila turned to Guldan and said, “Make it happen.”

The trio sketched a plan on a napkin for the trail to have access, including a handicapped-accessible ramp, to the top of part of the tank. A railing will separate the lookout from the part of the tank with the hatches. “This way there is a spot to direct people to,” said Guldan.

Two Harbors’s water treatment plant has three gravity filters with silica sand and anthracite. Chlorine is added to the water coming in from the lake, and then poly aluminum chloride for the rapid mix, although the raw water normally meets turbidity standards even without chemical addition. After flocculation, the water is filtered and sent to the chlorine tanks.

Elevation differences in Two Harbors aren’t as dramatic as in Duluth. From the plant the water goes through two booster stations in series to a 1.25-million-gallon tower in the northern part of the city and then to a second tower, this one 100,000 gallons, to the northwest. In addition to the booster stations and towers, Two Harbors has seven pressure reducing stations.

“The project that keeps on giving,” is how Guldan describes the work that began in 2016 and is encompassing the upgrade of the building with the high-service pumps, filter rehabilitation in the treatment plan, the chlorine contact tank, a new maintenance garage, and pipe and valve replacements. “This project will take care of their major needs for 20 years.”

The flocculation basins(above) and filters (below) in Two Harbors.

Go to top

When your water tower is down

By Shawn Mulhern and Ben Feldman, KLM Engineering

Do you have a water system that operates with only one tower or ground storage tank in your distribution system? If so, have you considered the impacts to your system if an issue arises and that reservoir needs to be removed from service for an extended period?

Here are some aspects to consider:

Well operations: Has your utility considered the electrical cost impact of operating a well 24/7 compared to normal usage? Operating 24/7 requires the use of at least one pressure relief valve on a hydrant to not exceed normal system pressure. Have you considered the amount of water being dumped or wasted? Have you considered the aquifer impact of significantly increasing the pumping from your well for this time period? Is the static/pumping water level and draw down going to be an issue? Do your wells have the capacity to operate in such a format? If a well were to go down or have maintenance issues during this time, would you be able to handle demand? Has your system been operated in such a manner in the past? Consider that operating outside of typical conditions can potentially lead to watermain breaks.

Treatment chemical usage: Have you considered how water quality will be maintained? Have you factored the increased cost of chemicals and additional treatment being wasted with the high volume of well pumping? If the project takes longer than two weeks, have you considered lead and copper impacts? Have you discussed availability of products with your material supplier?

Water discharge: Have you considered the water-wasting discharge location so you avoid discharge to water bodies and meet wastewater limits? Can the discharge location handle the water? Is dechlorination of the waste stream being performed to prevent the killing of wildlife?

Fire protection: Can your system maintain fire protection during this time? How does it impact utility insurance? What about auxiliary power during a fire or power outage? Is there a back-up system implanted?

Power outage: Does your system have backup power to address and maintain system pressure during an outage if the reservoir is out-of-service?

Project timing: Have you considered timing the project to coincide with low water usage periods? Have you informed stakeholders of ways to avoid system issues, such as not flushing watermains during this time or through water conservation measures by larger customers?

Cross-connection (for multi-tower systems): For multi-tower systems, do you have a cross-connection with another tower, separated with a pressure-reducing valve, that could be put into use?

The Minnesota Department of Health (MDH) has noticed the issuance of boil-water notices tends to occur more often for loss-of-pressure events associated with storage maintenance activities.To better avoid such incidents, MDH has some economical and proven recommendations to maintain distribution pressure and water quality that should be included when planning reservoir projects. These include auxiliary power at the wells, well pumps with variable frequency driven motors, and/or rentable, portable, pressure tanks for the duration the reservoir is out-of-service.

For more information, contact your MDH district engineer.

Can't get enough of water towers?

Water towers can be the most visible landmark in a city and a way to promote municipal pride. During the spring and summer of 2023, KSTP Television in the Twin Cities had a Water Tower Wednesday feature. The final installment profiled Kirk and Connie Brown, who created a website on which they have documented more than 1,000 water towers in Minnesota.

The site categorizes towers by city, county, and type. Along with a location of the tower and the year it was built, it has a picture of the tower. Check it out:

MDH proposing updates to health risk limits rules

The Minnesota Groundwater Protection Act authorizes the Minnesota Department of Health to develop and review health risk limits (HRLs) in cases of groundwater degradation. In recent years, MDH has been working on a rulemaking process to adopt water guidance values called “Health-Based Values” into Minnesota rules as HRLs. In November 2023, the Minnesota Department of Health adopted two new health risk limits (HRLs) for 17 contaminants and updated for another 19. The HRL for one contaminant, n-Hexane, was repealed.

In addition, in 2023 the Minnesota legislature required MDH to adopt an updated HRL for perfluorooctane sulfonate, a perfluoroalkyl substance, by June 2026. MDH will likely include updated values for perfluorooctanoate and other contaminants. A request for comments was issued in August.

More information:

Human Health-Based Water Guidance Table

Rules Amendments - Overview and Links

Go to top

Public Health Priority Points information

Projects submitted to the Drinking Water Revolving Fund are prioritized using rule-defined Public Health Priority Points to ensure that funding priority goes to projects that protect public health, provide adequate water supply, and assist communities with financial needs.

The proposed revisions would allow priority points to be assigned for projects relating to the removal of lead service lines and addressing contaminants of emerging concern when concentrations exceed a health advisory level. The proposed changes would protect public health by reducing the public’s exposure to harmful contaminants and assist communities with financial needs to remove or provide treatment to reduce contaminants.

More information:

Public Health Priority Points Rules

Go to top

Professional Operator Development Program announces new course for 2024

Conducted by the Minnesota Section of American Water Works Association in conjunction with utility partners and the Minnesota Department of Health, the Professional Operator Development program is an instructor-led series of lectures, hands-on lessons, and facility tours to enhance an operator’s knowledge of the basic principles needed to operate and manage an advanced public water system.

Open to anyone who has at least a Class C water operator license, the course covers general math, filtration, membrane and ion exchange, disinfection, water quality, regulations, source water, and sampling. The goal of the course is to build competence, confidence, and understanding of public water systems.

The next course will take place on Tuesdays from January 16 to March 19, 2024 from 7:30 a.m. to 2:30 p.m. at the Minneapolis Water Works membrane facility in Columbia Heights. The fee for the course is $300. Each week of attendance earns operators six contact hours toward the renewal of their licenses. An operator certification exam for students will be offered at the conclusion of the course.

Go to top

Quote of the quarter (and other gems)

A successful person is the one who went ahead and did the thing the rest of us never quite got around to doing.

A truly great library contains something to offend everyone.

We can measure our prosperity not by what we have but by what we take for granted.

Life is not about how fast you run, or how high you climb, but how well you bounce.

It isn’t what you know that counts; it’s what you can think of in time.

Go to top

Reminder to all water operators

When submitting water samples for analyses, remember to do the following:

- Take coliform samples on the distribution system, not at the wells or entry points.

- Write the Date Collected, Time Collected, and Collector’s Name on the lab form.

- Attach the label to each bottle (do not attach labels to the lab form).

- Include laboratory request forms with submitted samples.

- Do not use a rollerball or gel pen (the ink may run).

- Consult your monitoring plan(s) prior to collecting required compliance samples.

Notify your Minnesota Department of Health district engineer of any changes to your systems.

Go to top

Calendar

Operator training sponsored by the Minnesota Department of Health and Minnesota AWWA will be held in the coming months.

Register for schools and pay on-line:

Go to top